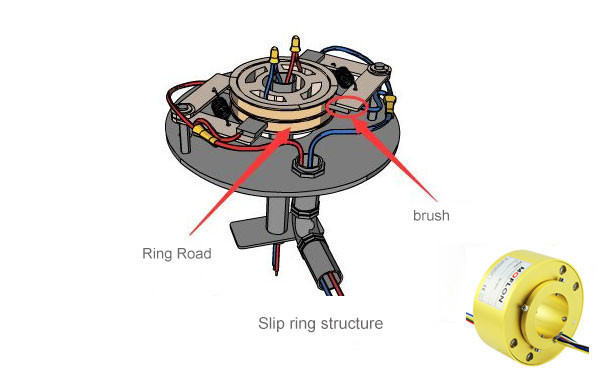

A slip ring is generally a device which has an electromechanical formation and is used to transfer current and data signals from the stationary source to the rotating component. There is various kind of slip rings and they all have a standard basic design. However, the design cue changes as per the requirements of the equipment. With the advancement in slip ring technology, the list of different type of slip ring is simply getting longer and longer.

As mentioned earlier, the some of the design aspects are changed and along with it in some cases, the material itself used for making the slip ring is altered to procure a right kind of slip ring which is a perfect fit for the concerned equipment. The performance of the slip ring is ideally dependent on the kind of the material used. The application of slip rings belongs which to make the electric connection possible in the first place to make the transmission possible at the first place is categorized in two different parts.

The first category is rotating electric connect this principle behind the use of modern slip rings like electric slip ring, or other electrical rotary joints. The second category of electrical connection is used in such slip rings which are employed in high-speed rail and it is commonly referred to as slip electric connect.

The transition of slip ring based on carbon brush contact to mercury contact slip ring and other forms of contact and non-contact has brought about a great in terms of operational efficiency. The only catch with such slip rings is that they are costlier than other slip rings. Also, mere name tagging to any slip ring won't suffice, the material is the key even if it is the modern slip rings. Everything boils down to the kind of material used for manufacturing them.

The most important issue with slip ring

Whether you choose any traditional slip ring or a modern slip ring. The main issue that plagues the efficiency of slip ring is its working life and maintenance as they both go hand in hand. If the slip rings are made up of quality materials the need for maintenance will be low and the life-span of the slip ring is automatically increased. There are some of the other factors which affect the performance of the slip ring include the operational condition, rotating speed and structure of slip ring.

Taking into consideration the variation in temperature

Most of the advanced are used in harsh condition and by harsh condition, we generally refer to changing temperature and variation in the level of humidity. There is a list of the list of things that needs to be checked to ascertain whether the slip ring can withstand the varying temperature. Firstly, the selection of contact material as the resistance which induced due to sliding contact can cause an increase in temperature with excessive heat. Secondly, the mounting pattern along with the positioning of the carbon holders must be precise and finally, the right kind of insulating material should be used to maintain the thermal level.