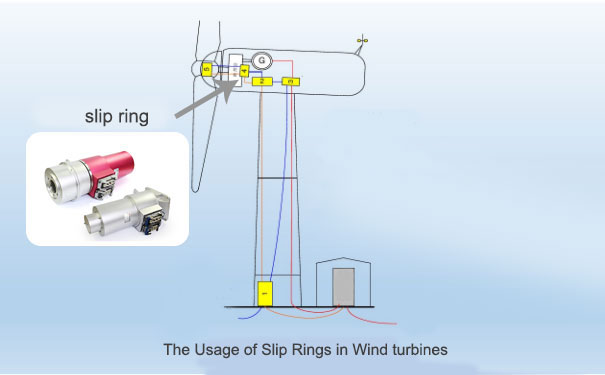

The slip rings of a wind turbine are a part of the slip ring class. These slip rings are high-tech products that have been applied in advanced military fields for a long time. They have also been applied in many civil applications as well in recent years. The slip rings are so widely used in the many industries due to its reliable and stable performance, high precision, low corrosion, long life, compact and noise free. Therefore, they are better suited for use in different weather conditions and geographical places.

Maintenance

The service life of a slip ring is generally a maximum of 20 years. But the guarantee period is of just 2 to 5 years. Not all the wind farm owners are ready or prepared to do the maintenance work on their wind turbines as the time goes. This is caused by lack of the staff required for the maintenance or by the lack of will and resources. Sometimes, they lack maintenance even with the required staff members. There needs to be a routine maintenance of the rings and unplanned maintenance check affects the performance of the slip rings and the service life. The unplanned maintenance helps to find out the deviation from the actual standards and help in telling the actual condition of the machine.

Brush Contacts

The brush contact that is used in the slip ring technology is made of advanced fiber brush technology or precious metal contact brushes are used to reduce the resistance between the wire brushes and the conductive ring leads. The low resistance and the low pressure of the brushes on the conductive rings because of the use of springs, reduce the force of friction of the brushes and reduces the corrosion. The reduction in corrosion keeps the surface of the rings and the brushes polished without corrosion. This help in reducing the electrical noise in the transmission of the electrical and data signals. Since the corrosion of the parts is very low the vibration due to corrosion is also low and the rings are not loosened and not displaced hampering the transmission.

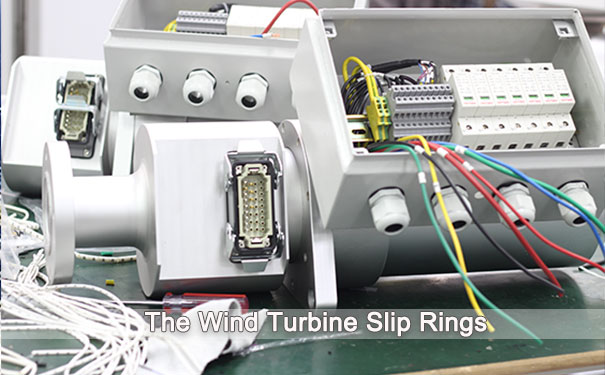

Insulation and Sealing

The brush and the conductive rings transmit power and data in rapid succession and there is a flow of multiple signals simultaneously. This is achieved by separate rings and brush for each of the signals. But the brushes and the rings are insulated from each other in order to stop the cross-connection of the signals and the obstruction of the signals and ensuring a continuity. The slip rings are also placed inside a sealed housing generally made of aluminium. This sealed housing does not allow the dust and debris from the outside environment to be accumulated in the internal parts of the slip rings. Coz this will cause the slip rings to be either stuck due to dust accumulation or corrosion.

The use of slip rings in different industries has played a very important role in the development of different industries. They have improved the condition of living as well as the service life of the devices. There are many more developments to come in the field of the rotary slip ring.