Before making a slip ring, the operating principles of slip ring must be well mastered.

Suitable materials are needed to select according to applications and specific parameters, such as current, voltage, signal frequency, connecting media, operating environment, working life, rotating speed and torque, etc.

Do the best industrial design according to mounting way, assembling process, electrical disturbance and aesthetics。

According to industrial design, the most suitable assembly technology can reduce the assembling difficulty and improve the assembly efficiency.

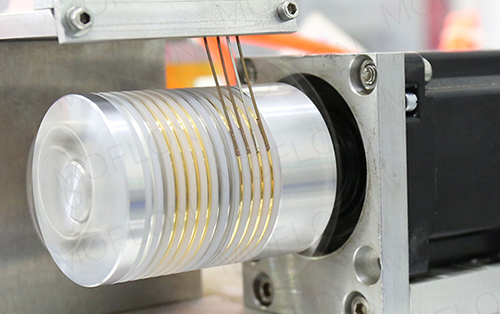

Strictly based on the engineering drawing, opening the mould, assembling products, reducing reject ratio by human error; Definitely, experienced and well-qualified assembly operator plays an essential role in improving the product quality.

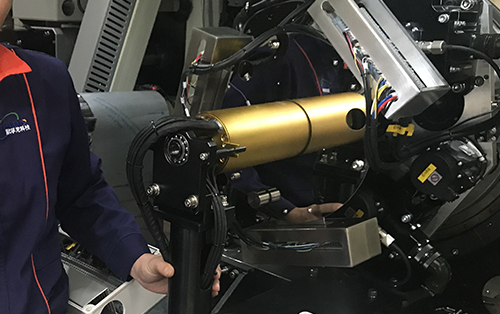

Testing products’ function and quality should be in strict accordance with parameters. For those products not up to standard should be rebuilt. A good quality testing reflects the spirit of the craftsman of manufacturer and also reflects manufacturer’s strong support and protecting for high-end brand products.