For more than 30 years, MOFLON has been a leading sealing products manufacturer and supplier to the agriculture sector.

MOFLON has been sealing all sorts of fluids, like bio-diesel fuel, liquid & solid fertilizers, and pesticides. Our slip rings are efficient and durable compared to our competitors' products. We protect your interests by sealing your farm machinery with high-tech and reliable sealing products.

In this guidebook, we shall discuss agriculture sealing solutions like slip rings, centre pivot irrigation, grain bins, silo unloader, combine harvesters, and rotary dairy barns.

Contents

Chapter 1: Agriculture sealing solutions

Chapter 2: Centre pivot irrigation

Chapter 1

Modern agriculture is laid on forward-based technologies and inventions, which bring continuous growth in agricultural productivity. This is precisely the vision of MOFLON Technologies. Our specialized engineers provide a variety of sealing solutions that facilitate functional reliability within harsh conditions.

The agricultural sector is facing big problems right now: the earth's population is increasing significantly. Researchers project that the need for food will double in the next three decades.

However, farm yield is, which directly translates to farmers' income is continually fluctuating due to weather and political factors. Besides, farm products are fetching low profits due to the perishable nature of farm yield and global competition.

Research has shown that reliability, durability, efficiency, and coziness are the farmers' priorities. Luckily, moflon slip rings address all these needs, and we are persistently setting higher standards in the sealing industry. From our 30 years of industry experience in product research, technology, and design, our sealing solutions work steadily, even in extreme conditions.

MOFLON's slip rings for agriculture enable possible performance in all parts of farm equipment. The right standard slip rings have been designed for axles, conductions, motors, and hydraulic systems.

MOFLON sealing products function reliably and with the best potential working dependability, particularly during planting and harvesting where downtime and breakdowns bring significant losses. The machines are required to bear up with extensive operations, extreme environmental conditions, and farm contaminants without being worn out. MOFLON's slip rings support farmers to realize this goal.

Farmers are also in need of sealing products that can withstand harsh temperatures. Most farm machinery manufacturers are not sure whether their equipment will be operating in Arctic cold, or in the odd environmental conditions of rice farms in Asia-pacific region, with the axle dipped in water, or the extensive Australian farmlands, where it is required to withstand the most prolonged potential courses at super speeds.

MOFLON's long-standing slip ring expertise makes our sealing solutions immune to the above factors. Our patented product inventions, which have been tested and proven right, are continually enlarging our sealing solutions' range of application.

With our innovative sealing solutions, we are one of the agricultural sector's established and worldwide suppliers. We have come up with unique slip rings featuring original, low-friction, and weightless features.

Agricultural tools are regularly exposed to various elements and contaminants. The contaminants can be either organic or chemical. Therefore, sealing products of farming machines must be designed to guard the machine's components from any contamination.

Agricultural tools are regularly exposed to various elements and contaminants. The contaminants can be either organic or chemical. Therefore, sealing products of farming machines must be designed to guard the machine's components from any contamination.

Slip rings used in agricultural machines must have strong structures and reliable efficiency since these equipment function in harsh environmental conditions. Seals are integral parts of these complex equipment because they require transmission of power and signals from static to moving parts. The slip rings must overcome different demanding conditions and function well in any type of setup.

MOFLON is determined to sort out power and signal transfer for these challenging conditions. Experienced engineers and superior production technology empower us to offer strong slip rings for agricultural machines.

When it comes to sealing solutions for the agriculture sector, customers from all over the world prefer MOFLON solutions to other products. We manufacturer our slip rings with typical and custom specifications to guard the machines against harsh temperatures and other impurities.

Chapter 2

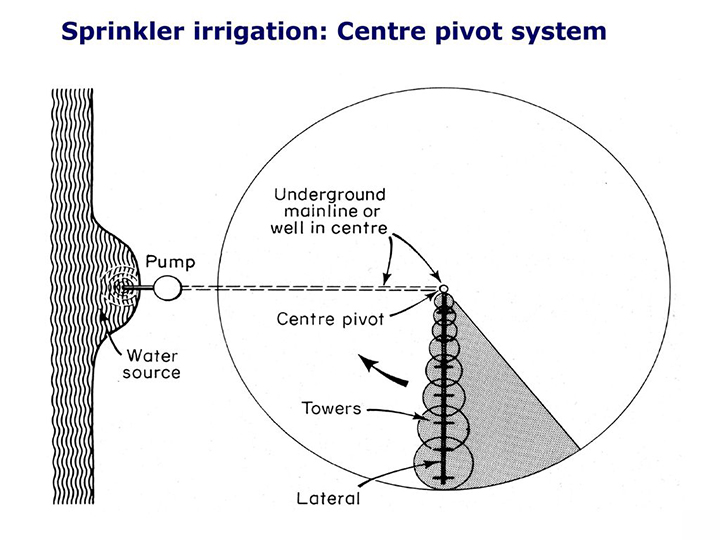

A centre pivot irrigation is a mobile pipe assembly which spins around a central axis fixed to a source of water. They are the most common sprinkler irrigation methods due to their supper efficiency, uniformity, the capacity to work in uneven terrain, and cost-effective purchasing costs, maintenance, and running expenses.

The history of CPIS started in Nebraska in 1950, and currently, they are spread all over the world. CPIS is probably the essential mechanical invention in the agricultural industry since the replacement of oxen by tractors.

CPIS move through the farms by electrically enabled wheels. Their sprinkler flow speeds surge towards the terminals of the pivot since the terminals rotate faster than the inner parts. The primary design limitation of this system is the inhibition of overflow at the pivot terminals, where flow rates are extremely higher.

As the name implies, centre pivots work in a circular manner around a central axis. The pivots can be used to spray water, liquid fertilizer, pesticides, and herbicides. Hence, centre pivots enhance the effectiveness of irrigation systems by applying one equipment to perform several roles.

Generators or electric current electronically power modern CPIS. Pivots can utilize either 120 or 480 VAC to run. 120 VAC is employed as the regulation circuit, driving the safety circuit, the onward and backward rotation of the pivot, and, particularly, the rotation of the Last Regular Drive Unit (LRDU).

On the other hand, the 480 VAC acts as the power circuit and provides the necessary current for the running of the drive components.

The equipment's control system controls the primary roles of the device. Based on the kind of control system of a CPIS, the control differs, but the machine functions in the same way.

When an operator instructs the control panel, a signal is transmitted down the pivot till it touches the LRDU. This ignites conduction of 480 VAC via a cable from the tower section to the motor. The LRDU rotates, either onwards or backward, as instructed by the control section.

Anytime a pivot rotates, it is directed by the LRDU- that moves till the switch arm, linking the final span to the second-last tower, is dragged to a position capable of triggering the subsequent tower. The two towers then rotate till the successive tower is stirred up, and the process continues along with the pivot till each tower spins.

When compared to other irrigation systems, CPIS is the best choice for irrigating farms effectively and efficiently. They control both the hand operated and big gun systems, and are more effective since they utilize less water.

CPIS contain drop nozzles which can be positioned near the soil and even below canopy points of crops. CPIS also spray water gently to the plants, minimizing the issue of surface runoff- that commonly affects hand operated and big gun sprinkler methods. In addition, unlike furrow methods, CPIS do not initiate much soil erosion, and the water spread below the pivots is very orderly.

Chapter 3

Grain bins are also known as silos, and they are meant to store and preserve grains, and silage for future use. They are popular devices in the agriculture sector, and the increase in population and farm yield has led to a surge in their demand.

Grain bins are also known as silos, and they are meant to store and preserve grains, and silage for future use. They are popular devices in the agriculture sector, and the increase in population and farm yield has led to a surge in their demand.

Grain bins are simple devices that do not contain many high-tech devices. Nevertheless, hey still demand careful installation, running, and maintenance.

Tall tower grain silos, which were common four decades ago, are still used on some parts of the world. However, horizontal grain bins are more popular nowadays, and they are available in several designs. Horizontal trench bins are constructed uphill and utilize soil as their walls. The second type of horizontal grain bins are known as bunker bins; they are constructed above the ground and are prevalent in feedlots and dairy farms.

At the moment, vertical elevators are the primary loading systems used in grain bins. Since most silos are tall, it is incredible to employ inclined conveyor systems to load them. Bucket elevators demand high capital investments, but they offer an active process of filling grain bins.

Some farmers opt for blower methods to load their bins; however, this is only possible when preserving livestock feeds. The blower system is not appropriate for loading grain meant for consumption since grain cracking is more rampant.

Since temperature within grain bins can be more than 900 Fahrenheit, it is advisable to cool grains that exceed 2,000 bushels.

Warming issues arise when air rich in moisture along a bin's outer surface drops and warm air in the middle rises, producing convectional circulations. The use of aeration to cool grains and eliminate moisture help preserve the quality of grains and prevents pest invasion.

In many silos, grains flow from the top and out via an outlet located at the centre of the bottom part. The outlet is equipped with an auger that offers transportation services to the carriers of the unloaded grains.

As the load flows out via the auger, it assumes a funnel outline at the top of the bin. If a person stands at that point, the flowing pressure can pull them into the process, resulting in severe injuries or even deaths.

Concrete stave grain bins employ slightly distinct unloading systems. Augers located at the top of the grain bins blow the stocked contents towards the middle of the bin, and then out via exits located at the sides of the bin.

Chapter 4

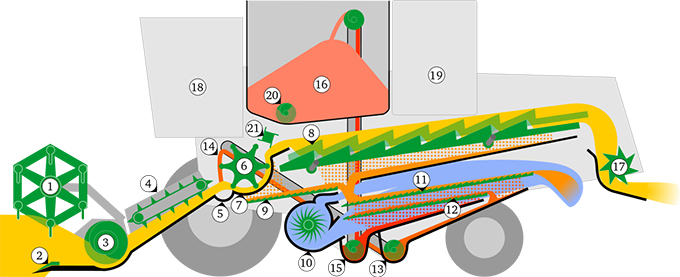

Combine harvesters are modern agricultural equipment which harvests cereals. The term is derived from the fact that the machine combines three distinct activities- harvesting, threshing, and winnowing- into one process.

Harvesting farm produces as a single operational activity saves time, labour, and eliminates post-harvest expenses. Besides, combine harvesters increase farm yields because the harvesting process is done more effectively, eventually making agriculture more profitable.

The primary component of a combine harvester is the detachable header component, which contains cutters to chop crops and a rotating reel to collect the cut cereals and store them in the auger. The header system can be of a standard model or a specialized one. Various header systems are applied to harvest different types of cereals.

These type of equipment work best in farmlands containing hard soils. They are the most common combine harvesters.

They contain tracks instead of wheels. They are preferred in muddy regions where wheels are likely to stick, reducing the efficiency of the machine. Track harvesters are mostly applied in reaping rice from wet fields.

These type of harvesters are driven by tractors, which are fixed unto them, and small scale cranes pull the tractors. Tractor-based harvesters function well in large farms with loose soils.

Combine harvesters will solve the swelling problem of obtaining an adequate number of skilled and trustworthy farm workers. Rural-urban migration is affecting many economies negatively by creating a severe scarcity of farm labour.

Additionally, labour wages have also sky-rocketed, making it even more challenging for capital-strapped agriculturalists. Since combine harvesters can execute all duties formerly performed by labourers, the problem of labour shortage and high labour expenses are being resolved in a significant way.

Chapter 5

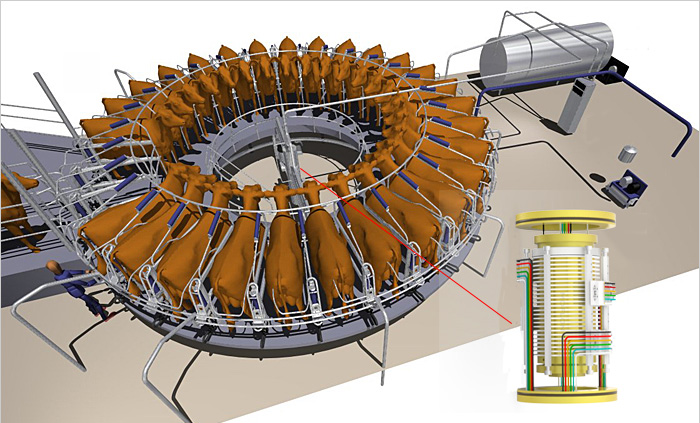

Rotary dairy barns resemble playing merry-go-rounds. However, in dairy barns, cows are put in rectangular-like sections, permitting attendants to fix milking machines to the teats.

The equipment moves quite slowly, allowing cows to get in and out of the structure at constant intervals.

Cows enter the rotary dairy to be milked, and they are later returned to their feeding or resting dens. They can also be milked within their resting rooms with the help of bucket milkers or a pipe milking structure.

Automatic milking methods usually function without people being there to oversee the process and have available for the last ten years on large scale farms.

The primary benefits of rotary dairy barns, when compared to manual milking of animals, is that they improve labour effectiveness, offer ergonomic benefits, and minimizes the risk of harm brought by upsetting and repetitive stress.

In a rotary dairy barn, the highest efficiency is attained when the farmer's routine work schedule (majorly comprising of the length of time required to fix a cluster) and the equipment speed are closely tied.

The regular work schedule is the overall duration of milking one cow. Routine work duration determines the number of cows that can be milked within one hour.

In a rotary dairy barn, most of the duties are automated unlike in a herringbone; hence, cluster fixing is the primary duty, apart from reattaching pipes, regulating the backing entry, or idle time when the machine is moving sluggishly.

Less routine work duration will intensify the number of animals that can be assisted. The throughput (highest number of animals that can be milked in an hour) is estimated by dividing 3600 (the number of seconds within one hour) by the duty routine duration.

Rotary dairy barns are very useful, but many factors must be kept constant outside the rotary for maximum productivity. The animals must be clean before entering the rotating structure.

Besides, traffic patterns must be handled with negligible human interruption, and distances to the rotary must also be sensible.

Whether a farmer's goals are animal comfort, simplicity of activities, rotary dairy barns can play a significant role in the agriculture sector. Animals enjoy comfortable journeys, peaceful and at their speed, which directly translates into high productivity.

Rotary dairy barns can perform the milking process faster and produce more yields with proper routines, reliability, and right protocols compared to other milking systems.

Chapter 6

For over 30 years, MOFLON has been manufacturing and designing agricultural sealing solutions that tolerate odd working conditions. We consider all requirements, like efficiency, extreme weather conditions, and wear and tear factors, to offer our clients the best slip rings that are stable and durable.

Visit our website today, and make your orders. We offer both standard and custom sealing solutions.

I hope you have enjoyed reading the guide. Remember to drop any question concerning this topic in the comment section below.