What is a Slip Ring?

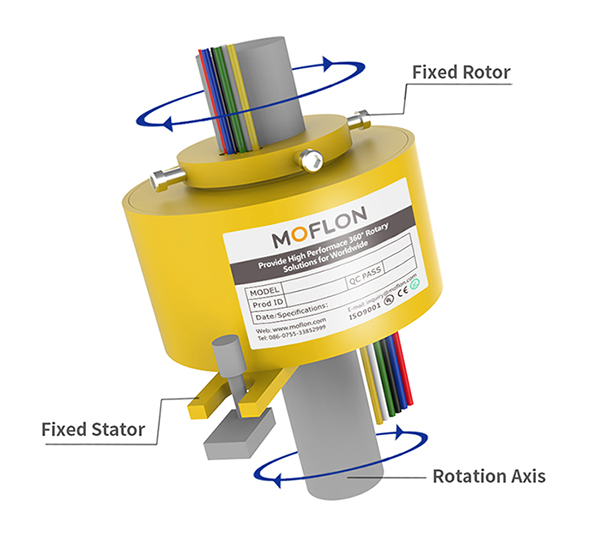

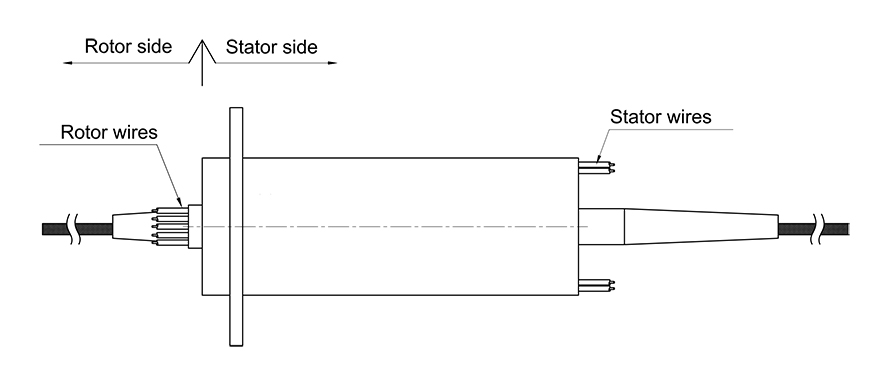

A slip ring is a device that is used to connect the stationary and rotational part of a device, but it actually has two purposes hidden inside one little device.

Slip ring can also provide a transfer of data and power without any damage occurring on the stationary device.

With many different types and purposes a slip ring can be used for, it is important to choose a correct slip ring for a needed purpose.

Slip rings are also known as rotary electrical contacts, electrical slip rings, or even as commutators.

They’re also built using different materials and they come in different shapes and sizes to fit different devices and machines and to provide a much needed function in the most versatile way.

Therefore, you can find slip rings being used across many industries, including rotary constructions and such machinery.

With so many different types, alongside transmission of power and data, some slip rings can also provide liquid transmission, as well as rotary connection and support.

Also, all of the industries are considered in the making of slip rings so they can withstand temperatures and pressure required in different scenarios. Therefore, slip rings can also be custom built upon the order.

Slip rings are also used for speed control in rotational devices by being able to adjust the speed of the motor and gradually build the needed power. Therefore, slip rings might be a small device, but they’re actually very convenient and are built up to perfection so they offer smooth operation without any hiccups in the performance.

How to Install a Slip Ring?

Slip rings are small devices and they don’t take up a lot of space, but they should be installed properly according to the guidelines provided by the slip ring manufacturer to avoid any error in the operation.

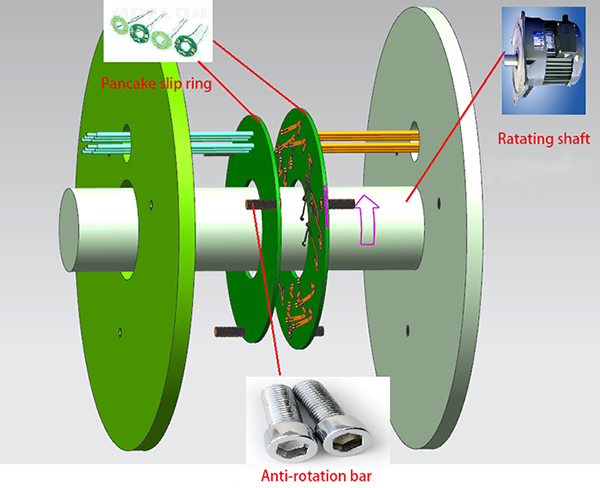

There are a couple of different ways a slip ring can be installed, and the most common way to install a slip ring is to place the ring inside the hole of a static part of the machine or a device. After that, the slip ring should be secured through bolts or adhesive to stay in place and connected with the stationary part at all times.

Some slip rings can also come with installation brackets that can help with assembly, but they’re not always necessary.

However, one thing to keep in mind is that it’s always a good idea to use the same amount of torque to tighten all bolts to prevent over tightening or loose bolts that could come off upon the use.

Also, ensuring that there’s no additional weight on the slip rings after installation is important to make sure slip rings don’t malfunction and that they operate as smoothly as possible.

Lastly, after a successful slip ring installation, a protective cover that would keep the slip ring from dust or moisture is advised. Most slip rings nowadays come with a protective cover on it which is more than enough protection.

Why Use a Slip Ring?

Slip rings can be found in so many devices and machines nowadays, but why are they so common today?

Unlike any other device on the market, slip rings can connect two parts of a machine, where one part can rotate and the other can stay stationary without causing any malfunction between two parts of the device.

On top of that, slip rings can also ensure an undisturbed transmission of power or data through a signal which is a much needed feature for some devices and machines that use slip rings.

Rotating bodies of a machine that require a signal and power such as an excavator widely rely on slip rings as the middle man that provides the connection.

Not only do slip rings transmit power, but they can also modulate and regulate the power so they’re also widely used in motors that require precise energy transmission, but also in machines that require gradual power build up.

And with so many slip ring types, they’ve become a simple and versatile solution to many different needs when it comes down to devices that have stationary and moving parts.

How to Use a Slip Ring?

Installing a slip ring is a simple process, and once a slip ring is installed, it will always do its function, unless it is removed from a device or a machine.

Therefore, it’s more about how you plan to integrate a slip ring into your device and the place you’ll install it on. Since slip rings connect the stationary and rotational part of a device, it’s almost always placed in such situations to bridge the gap between these two parts of a device.

However, slip rings are also strategically placed in places where they can help transmit power and data through signals so two parts of a device aren’t only connected physically, but can also be connected virtually through sensors and readings.

Since slip rings are very stable and reliable, once you know the type of slip ring you need and the way you will install a slip ring so your device or machine benefits from it, the whole job is done after the installation.

So while you can’t physically control a slip ring, you can use it to improve the function of a device or a machine.

How to Choose a Slip Ring?

Slip rings come in many different types so it’s important to know what purpose you’ll want to achieve using a slip ring, device you’ll use a slip ring on, and the performance you expect from the device, as well as the additional factors such as the temperatures, working temperatures, and pressure requirements.

Two of the most important things to consider when choosing a slip ring are the voltage drop and a current flow through the slip ring.

These two factors will tell you if a certain slip ring is good enough for your device or a machine.

However, with so many different types we have access to nowadays, choosing a slip ring is fairly easy because slip rings are categorized for industries and purposes.

Some of the most common slip ring types include:

●Pancake slip ringAnd some of the most common industry-type slip rings fit the following industries:

●ConstructionLastly, upon choosing a slip ring, keep in mind that they have a number of working hours they can withstand, and there are a couple of additional factors to consider such as the working pressure and temperature it can withstand.

However, slip rings can also be maintained so they have no error.

When you find a slip ring that fits your industry, purpose, a machine/device, lastly have a look at the mechanical safety parameters and configuration to ensure a proper fit.