Wind Turbines: A guidebook for domestic and industrial wind turbines is the most comprehensive, up-to-date, and research-based guide on every aspect of wind energy turbines. Wind turbines are one of the cheapest domestic and commercial renewable energy sources. Based on your wind resource, a wind turbine can minimize your power bills by 50%-90%, assist you in getting out of the high expenses of putting up electric power lines to remote areas, avoid power breakouts, and more importantly, it is eco-friendly.

In this guidebook, we shall learn the basics of wind turbines, the types, sizes, their efficiency, the pros and cons of wind turbines, how they function, installation of wind turbines, their maintenance, slip rings for wind turbines, and wind turbine costs. Each chapter comprises of a research outline with a comprehensive evaluation of all the concepts within that topic.

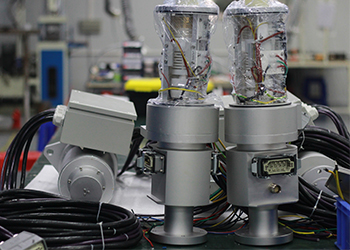

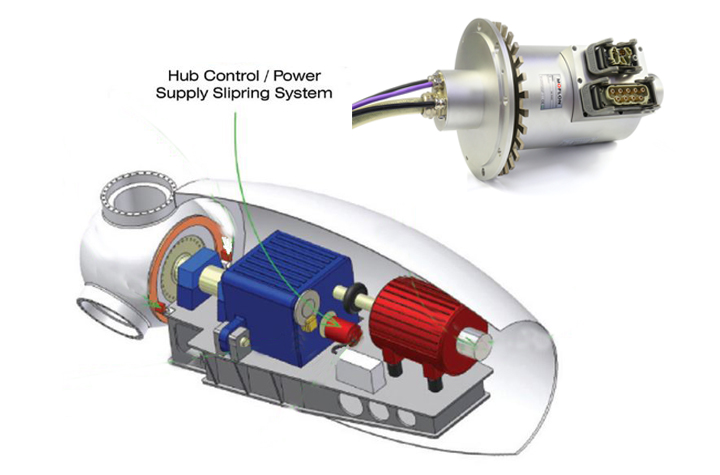

Wind turbines demand steady transmission of energy and data signals right from the nacelle to the control section of the rotary vanes. MOFLON's slip rings offer the performance and reliability required in harsh environments.

The Bottom Line

Costly downtime of wind turbines can be reduced by applying fiber brushes and durable equipment in the construction of slip rings.

For more information concerning how MOFLON wind turbine slip rings can be designed to meet your specifications, contact us today, and you will not be disappointed. Below are some of the outstanding features of MOFLON wind turbine slip rings that make them differ from the rest:

For more information concerning how MOFLON wind turbine slip rings can be designed to meet your specifications, contact us today, and you will not be disappointed. Below are some of the outstanding features of MOFLON wind turbine slip rings that make them differ from the rest:

They can function under diverse temperatures.

Are highly reliable.

They do not require regular assessments.

They do not need to be lubricated.

They have less wear debris effect.

Contents

Chapter 1: What is a wind turbine

Chapter 2: Wind Turbines - Types, Sizes, Efficiency

Chapter 3 : Wind Turbines - Pros and Cons

Chapter 4: Functioning of Wind Turbines

Chapter 5: Wind turbine installation

Chapter 6: Wind turbine maintenance

Chapter 7: slip ring for wind turbine

Chapter 8: The Cost of Wind Turbines

Chapter 9: The Future of Wind Turbines

Chapter 1

Wind turbines are modifications of traditional windmills that were common in the 19th Century. The purpose of wind turbines is to minimize dependency on fossil fuels to produce energy and also to generate power in a renewable and eco-friendly manner.

i)Wind Turbine Facts

i)Wind Turbine FactsWind turbines function by utilizing the kinetic power of moving wind, which drives the blades of the turbine and rotates a motor which turns the kinetic energy into mechanical energy for domestic and industrial use.

In a layman language, wind turbines function contrary to a fan. Rather than using electric power to blow wind, like a fan, they use the wind to create electrical energy. The wind drives the vanes that in turn, rotate a connected generator to yield electrical power.

People have been using wind power for decades. Right from the ancient Holland to ranches in the US, windmills have been applied to pump water and grind grains. In the contemporary world, the windmill's revolutionary form- a wind turbine- uses wind power to produce electrical energy.

Just like windmills, wind turbines are constructed on towers to harness more kinetic power. At 30 meters above the ground, they capitalize on the quick and calm form of wind. Turbines harvest the kinetic energy of winds using their vanes. Typically, a wind turbine is fitted with two to three vanes to create a rotor.

A blade behaves like aircraft wings. When the wind blows, a compact of low-pressure wind is created beneath the vane. The low-pressure wind compact then pulls the vane towards it, making the rotor to rotate. The process is known as lifting. The power caused by the lift has been established to be more powerful than the wind's strength against the front surface of the vane, and this is what is known as drag.

A combination of these two factors makes the rotor to rotate and in turn, makes the connected generator to generate electrical power.

Turbines can serve in stand-alone/unaccompanied use cases; they can be linked to utility energy grids, like generators, or used with photovoltaic systems. For industrial use, several wind turbines are typically set up together to create a wind plant. Many power distributors in many countries employ wind plants to distribute electricity to consumers.

Unaccompanied turbines are basically for water pumping and communications. Nevertheless, homes and farms located in windy regions can also employ these type of turbines to minimize their power expenses.

Small wind turbines have been established as useful distributed power alternatives- small, modular energy-producing inventions, which are combined to facilitate the functioning of power supply systems.

Wind energy is among the highly demanded renewable energy sources in the word. Its use is on the rise globally, partly because installation expenses are decreasing yearly. Worldwide installed wind turbine capacity onshore and offshore has risen by a factor of about 75 in the last two decades, surging from 7.5 gigawatts in 1977 to 574 gigawatts in 2018.

Wind energy is among the highly demanded renewable energy sources in the word. Its use is on the rise globally, partly because installation expenses are decreasing yearly. Worldwide installed wind turbine capacity onshore and offshore has risen by a factor of about 75 in the last two decades, surging from 7.5 gigawatts in 1977 to 574 gigawatts in 2018.

Generation of wind power doubled between 2009 and 2013, and in 2016 wind power comprised 16% of electricity produced by renewable sources. Most parts of the earth possess robust wind speeds, but the ideal regions for producing wind energy are mostly remote regions. Offshore wind energy presents excellent potential.

Wind turbine capacity has risen with time. In the 1980s, most turbines had a rated capacity of 0.05 megawatts coupled with a rotor radius of about 7.5 meters. The contemporary wind energy plants possess turbine capacities of almost 2 megawatts onshore and 3 to 5 megawatts offshore.

Industrial wind turbines have a capacity of up to 8 megawatts and a rotor radius of about 82 meters.

Three significant aspects influence wind energy production in a place: the speed of the wind, air density, and blade diameter. More importantly, wind turbines should be constructed in locations with more regular winds.

The speed of wind dramatically affects the quantity of power produced by a wind turbine. Research shows that higher wind speeds produce more energy since stronger winds empower the vanes to spin faster. Faster spinning directly translates to more mechanical energy that also brings more electrical energy from the connected generator.

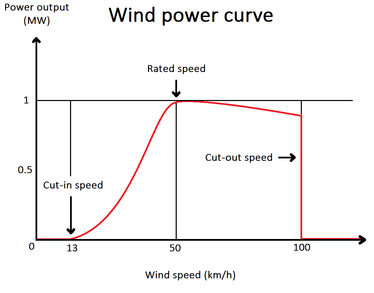

Turbines are intended to function within an appropriate measure of wind speeds. The restrictions of the measure are called the cut-in speed and cut-out speed. The first term refers to the point where the turbine can create energy while the latter is the mark where the turbine should be switched off to prevent damage to the machine.

The power output of a wind turbine is influenced by the surrounding air density, which results from pressure, altitude, and temperature. Research has established that dense air applies more pressure on turbine rotors resulting in more energy production.

Wind turbines are meant to maximize the rotor vane diameter to optimize energy generation. Larger vanes enable turbines to harness more of the kinetic power of wind by blowing more air via the rotors. But, large blades demand more space and higher wind speeds to function well.

Generally, turbines should be fitted at a spacing that is four times the rotor diameter. The spacing is essential to prevent turbine interruptions that reduce energy output.

I suppose you have heard the debate that renewable energy sources are not reliable since the wind blows occasionally and the sun shines only in some hours of daytime. We all agree that renewable sources of energy are variable because no one can make the wind to blow, and the sun to shine day and night. Nature always has its way. However, this doesn't imply that significant capacities of wind and sun cannot be harvested into power grids.

Wind turbines only function when the wind blows; when it is not blowing, power will be offered by other sources of energy, like gas and hydro.

There is much confusion concerning the reliability of various sources of energy. It's time to clear the air concerning this confusion — no energy source functions throughout minus stopping. Even reliable sources like nuclear energy are affected by unanticipated 'outages' that require reactors to be stopped for essential safety reasons. Unreliability of this sort is more problematic compared to that of wind energy since the quantities of electricity used are more.

The truth is that you should never depend on wind power alone for provision of all your power needs. Nevertheless, it is also good to note that wind energy and hydro energy are perfectly fit for each other.

Is the tie between the tower and the subsoil and comprises of all the stationary and moving weights of the turbine. The foundations of most turbines are circular and are made up of steel mesh, which is accompanied by a concrete material.

The circular design ensures that the effect of the forces is similar in any wind direction and the amount of concrete and steel to be mounted is noticeably minimized. Using the dugout soil to fill the foundation brings more stability even in a smaller radius.

Can be defined as the biggest and weightiest section of a wind turbine. Most towers range between 50 – 150 meters and weigh many hundred tonnes. Coupled with other factors, the height of the tower is important for the energy output generated by the turbine. The taller the tower, the less the weight of turbulence and the higher the wind speeds. As times go by, we will be witnessing increasing hub heights that can harness higher power output.

Tubular concrete assemblies that are ferried to the turbine sites in portions and put up in situ are the recommended tower designs for most wind turbines.

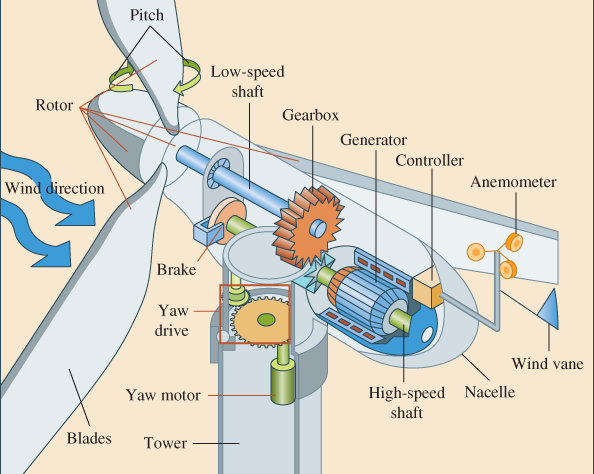

It is used to harvest wind energy and transmit it to the drivetrain. The rotor hub links the rotor vanes to the rest of the equipment and passes the energy to the rotor shaft. In most wind turbines, regulation of their speeds can also be made through the rotor vanes.

The blade angle tuning (pitch control) enables control of the energy production of the equipment at great wind speeds. The placement of the rotor blades in line with the wind can be regulated by use of pitch motors, hence dynamically adjusting the aerodynamics. This strategy is vital since the rotors employed nowadays with diameters of between 35–60 meters create high forces which are challenging to control with mechanical brakes.

The adjusted blade design that also utilizes the inner segment of the rotor disc and hence raising its effectiveness is essential in the modern rotor blade geometry. The vane tips can also be adjusted concerning noise pollution and power output.

This section is found on the upper side of the tower and houses the entire machine geometry of a turbine. The major part of the nacelle is the drivetrain that is made up of a rotor hub, shaft, and generator. The contemporary wind turbines portray the shape of an egg to house the bigger annular generator in the nacelle.

The nacelle is frequently fixed on the tower because of the integral yaw regulation, and it can be driven by azimuth motors, which are employed to spin the turbine optimally into the prevalent direction of the wind.

An instrument for measuring and transmitting the speed of the wind to the regulator.

They lift and move when the wind hits them, enabling the rotor to rotate.

Used for controlling the rotor mechanically, electrically, and hydraulically in emergencies.

Ignites the turbine at speeds of approximately 8–16 mph and closes it at 55 mph. The machine is turned off at speeds of 55 mph to avoid damages due to high wind speeds.

Acts as a link between the low-speed shaft and the high-speed shaft and increases the turning speeds from 30-60 rpm to almost 1,000-1,800 rpm- the turning speed mandatory for most generators to generate power. A gearbox is a steep section of a turbine, and researchers are investigating "direct-drive" generators which function at slow turning speeds and do not require gearboxes.

Generates 60-cycle AL power, and is usually an off-the-shelf induction type.

Responsible for driving the generator.

It spins the low-speed shaft at around 30-60 rpm.

Moves blades from the direction of the wind to regulate the rotor speed, and to prevent it from facing in the course of violent winds or week ones that can't generate energy.

An instrument that measures the direction of wind and links with the yaw drive to position the wind turbine in line with the direction of the wind.

Positions upwind machines to enable them to encounter the wind when the direction is altered. Downwind devices do not need a yaw drive since the wind automatically upsets the rotor from it.

Chapter 2

There are three categories of wind turbines: Horizontal Axis Turbines, Vertical Axis Turbines, and Ducted Turbines.

These are the popular types of wind turbines. All parts of the machine are located on the uppermost part of the tower with blades facing the direction of the wind. When the wind blows against the edges, it triggers spinning of the shaft, which contains a gear at one end for rotating the generator. The generator, in turn, creates energy and transmits it to a power grid. The turbine also includes some essential parts inside, which brings efficiency, as discussed in chapter 2.

Wind turbine vanes are tightened well to inhibit them from being pressed into the tower by strong winds. Besides, the vanes are fixed at an appropriate position in front of the tower and are occasionally slanted. Downwind turbines have been constructed, in spite of the issue of turbulence, since they do not require an extra method for maintaining them in the direction of the wind, and since in strong winds, the vanes can be bent to minimize their swept region and hence their wind resistance.

Wind turbine vanes are tightened well to inhibit them from being pressed into the tower by strong winds. Besides, the vanes are fixed at an appropriate position in front of the tower and are occasionally slanted. Downwind turbines have been constructed, in spite of the issue of turbulence, since they do not require an extra method for maintaining them in the direction of the wind, and since in strong winds, the vanes can be bent to minimize their swept region and hence their wind resistance.

Because turbulence causes fatigue issues, and reliability is essential, most horizontal turbines are upwind equipment. We have three types of horizontal wind turbines:

On-Shore. High altitude areas are the preferred sites of onshore turbines. Denmark, Spain, and Portugal are the pioneers of this type of turbines.

Offshore Turbine. This is a product of a revolutionary invention which encouraged engineers to construct wind power harnessing turbines in water bodies. Offshore turbines exploit the strong ocean winds, and they are not characterized by the issue of noise since they are located far away from homes. The UK is best known for high production of wind energy using offshore turbines.

Near-Shore Turbines. They are erected near the shores of water to take advantage of coastal lands and sea breezes to generate energy.

In these types of turbines, the blades are fitted vertically to the ground. All parts of this type of turbines are placed near the ground. We have four types of vertical axis turbines:

Darrieus/Eggbeater Turbines. Are baptized after French creator, Georges Darrieus. Darrieus turbines have excellent efficiency but create high torque current and cyclical pressure on the tower that causes low reliability. They require an external source of power to begin turning.

Giromill. They are a modification of Darrieus with straight instead of curved vanes. The cyclo-turbine type contains a variable pitch to minimize torque pulsation.

Savonius Turbines. These are drag-type machines containing two scoops, which are applied in anemometers, Flettner vents, and in high-dependency low-efficiency energy turbines.

Twisted Savonius. Are adapted Savonius characterized by long helical scoops to offer smooth torque. They are mostly applied in roofs and boats.

This type of turbine is fitted at edges of buildings to exploit the airflow along buildings sides. The wind blows upwards, clasping the walls before entering the ducts. Ducted turbines are ordinarily small, presenting less visual effect to buildings.

Wind energy turbines can be classified into three sizes, each with its distinct use. The size is determined mainly by the turbine's application.

Residential Turbines: Less than 30 kW

Select a size depending on your power needs.

They have diameters of 1 to 13 meters.

Their height ranges from 18 to 37 meters.

Medium Turbines: 30 to 500 kW

They are mainly applied when there is a significant electrical load.

Their diameters range from 13 to 30 meters.

Their heights vary from 35 to 50 meters high.

Commercial Scale Turbines: 500 kW to 2 MW

They are typically connected into a power grid, and they are not sized to one electrical load.

Their diameters range from 47 to 90 meters.

Their heights vary from 50 to 80 meters high.

Efficiency denotes to the quantity of power that is produced as a ratio of the total power available. It is a necessary measure for equipment consuming costly fuels, are non-renewable or pose disposable issues, like coal, natural gas, and radioactive elements.

However, efficiency is insignificant to wind turbines since they do not use fuels, therefore, eliminating the cost and limited aspects of fuel. They are therefore not meant to capitalize on any measure of effectiveness, but to attain the desired cost-effectiveness. Remember, capacity differs from efficiency.

The technical perspective where efficiency is used in wind turbines lies in the aerodynamic effectiveness of the vanes. In other words, this is the extent of the quantity of power generated from the wind by the vanes. This measure contains a theoretical threshold known as the Betz limit, which is 59.3%. The aerodynamic effectiveness of the blades depends on the speed of the wind but is approximately 80% of the maximum attainable.

Chapter 3

In this chapter, we shall discuss the pros and cons of each type of wind turbines separately.

The blades are positioned towards the center of the turbine of gravity to bring more stability.

They can wing warp giving the turbine vanes the position of spinning.

They can pitch the rotor blades during storms to prevent damages.

Have tall towers that enable access to steady winds in regions with shears.

The tall towers further enable erection on uneven lands and in water bodies.

Horizontal axis turbines can be put up in forests just above the tree lines.

Are challenging to function in low altitude winds.

Are expensive to ferry (20% of machine expenses).

Hard to put up (call for tall cranes and experienced engineers).

Affect nearby radars.

Are difficult to maintain.

They require cheap maintenance costs.

Have cost-effective erection and transportation expenses.

They are not directional.

They are more effective at hilltops.

Their blades are regularly rotating back to the wind igniting drags.

They are less effective.

They function well in lower strong winds.

They have low ignition torque and might need the power to ignite.

They have a less visual effect on buildings layout compared to horizontal and vertical axis turbines.

They utilize well-unused rooftops.

They enable power demands to be achieved on-site dodging transmission expenses brought by centralized power production.

They are fit for urban areas, but not residential houses (only suitable for high-rise towers).

They are uni-directional, meaning they are at immovable positions and rely on air moving in the right direction.

Prior research must be conducted to determine power generation potential.

Chapter 4

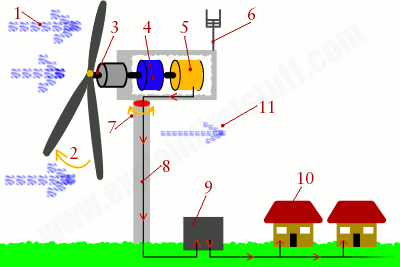

1.Wind (blowing air which has kinetic energy) moves in the direction of a turbine's rotor vanes.

2.The vanes rotate around, harvesting the kinetic power, and moving the drive shaft which holds them. Though the outmost edges of the blades turn faster, the drive shaft that holds then spins a bit slowly.

3.Blades of cutting-edge turbines can spin on the hub at the front to encounter the moving wind at the ideal position for maximum output of energy. For large turbines, small electric motors turn the vanes back and forward under defined electronic regulation. For small turbines, the pitch regulation is mostly entirely mechanical. Nevertheless, most turbines contain static rotors and lack of pitch regulation.

3.Blades of cutting-edge turbines can spin on the hub at the front to encounter the moving wind at the ideal position for maximum output of energy. For large turbines, small electric motors turn the vanes back and forward under defined electronic regulation. For small turbines, the pitch regulation is mostly entirely mechanical. Nevertheless, most turbines contain static rotors and lack of pitch regulation.

4.Within the nacelle, the gearbox turns the low-speed spinning of the drive shaft to fast spinning capable of running the generator effectively.

5.The generator then receives the kinetic power from the rotating drive shaft and converts it into electricity. Operating under ideal conditions, a 2 MW generator can produce 2 million watts of electrical energy at 700 volts.

6.Anemometers and wind vanes positioned at the rear part of the nacelle produce measurements of the speed and direction of wind respectively.

7.The yaw motor uses these measurements to move the whole upper section of the machine to face the blowing wind for maximum power output.

8.The electricity created by the generator is conducted via a cable stretching from the turbine tower.

9.A secondary transformer amplifies the electrical energy by almost 50 times to be transmitted effectively to the power system.

10.Consumers receive clean and renewable energy since wind turbines do not emit greenhouse gases as they run.

11.Wind continues to flow against the blades of the equipment, but a bit slower and more violent because the turbine has interrupted its flow.

Chapter 5

The duration and cost of the installation process rely on the size and type of equipment being fixed. Before the installation process starts, it is crucial to carry out a survey of the site and study the area's wind speeds for about three months.

Based on the two factors mentioned above, this step may demand heavy machineries like excavators and cranes. It is advisable to give the foundation two lays to harden up before proceeding to the second step.

Trenches are necessary for the cables that stretch from the wind turbines to the regulation area and inverter.

Based on the turbine size, the step may demand the help of a crane.

Specialized personnel will link the turbine DC supply with the gearbox and the inverter. Once this is done, the AC supply of the inverter is related to the farm's electricity system or power grid. Safety measure is accomplished by erecting other machines like isolators.

To link the turbine with the power grid, the engineer communicates with the power supplier of that locality.

The engineer is supposed to carry out the last electrical safety and performance assessments before launching the wind turbine.

Chapter 6

Maintenance experts confess that regular lubrication of small quantities of grease prolongs the life expectancy of bearings and seals. However, extensive periods of hub creeping is physically and emotionally challenging. The right tactic of countering this is a consolidated and programmed lubrication system for turbines. Consolidated lubrications strategies are thought to minimize operating expenses, bring operational reliability, and lengthen service periods.

A modern lubricator system known as 24-Vdc electric-powered equipment greases big-sized turbines without affecting the hydraulic systems. This lubricator is applied with a hose reel and grease gun.

Hydraulic spare part firms are working on more efficient lubrication-oil inventions for turbine gearboxes. The designs are thought to be accompanied with filters, pumps, coolers, heaters, and manifolds and pipes to link parts. The benefit of these systems is that the products are carefully verified and established to have the guarantee of reliability.

Tools. The tools for maintaining wind turbines are similar to those used in general engineering. However, these tools are fixed with tethers to avoid dropping many meters to the surface.

Chapter 7

Slip rings offer steady transmission of energy and signals from fixed cables of the nacelle to spinning parts of the hub. slip ring designs are mostly metals and graphite or precious-metal wire brush that links with the outer diameter of the spinning metal ring. As it rotates, electrical signals are transmitted via the brush.

moflon slip rings can be mounted and forgotten. Wind turbine slip rings from our competitors need regular maintenance to remove debris, oil, and re-lubricate.

Slip rings are employed in wind turbines for various safety-related purposes, which greatly influence the accessibility and effectiveness of the turbine. MOFLON slip rings are precisely manufactured for such uses and can provide conforming tastes, particularly regarding efficiency and quality. Wind strength specific needs concerning shock and vibration, diverse temperatures and durability are also important aspects we consider significantly.

The high probability of customization for many slip rings implies that big orders will decrease the unit expenses significantly. The skilled labour force needed to design custom assemblies makes price breaks to rely mainly on the run amount than the estimated yearly usage of the equipment. Customization additionally dictates the client to provide comprehensive information concerning the equipment's design specifications before a manufacturer can give a precise price estimate.

Energy demands pose the most significant influence on the price of wind turbine sling rings. An ordinary slip ring for 600-watt equipment can be bought at $500 while that of a 20-kilowatt turbine can be acquired at $95,000. The more the power demands, the bigger the size of the circuitry, the bore, brushes, and electrical insulation. The density of a wind turbine circuitry also brings a high impact on the price of the slip ring, because a complex circuitry demands the ring to possess a bigger bore.

This feature is a slip ring's most custom-made part since the brush and center leads might need distinct harnesses. Customization is common in this part since every wire of the circuitry might hold a separate current and signal. Besides, some wires might need jackets for extra insulation or connectors which enable them to be easily attached and detached.

A bigger bore size usually raises a slip ring's price. Nevertheless, a minor bore size may also raise the price when it calls for the reduction of parts. In some instances, the bore might be bigger than that specified by its circuitry. For instance, some wind turbines need a slip ring to fit over a bigger shaft or put up with extra lines for fluids.

The cost of a slip ring is also influenced by the kind of enclosure it has, which is also influenced by the specified mounting angle. A vertical mounting may require just a simple enclosure to offer the maximum equipment protection from external conditions. Slip rings that are fixed beneath a hydraulic spin may demand a wrapped enclosure to guard it against the media flowing through the swivel.

Chapter 8

Turbines below 100 kWh cost approximately $3,000-$8,000 for one kWh capacity. A 10 kWh wind turbine (the appropriate size for generating electricity to a big home) may have installation expenses of $50,000-$80,000.

Research shows that turbines have important economies of scale in the modern world. Minor farms or residential scale machines are generally cheap but are slightly expensive in terms of kilowatts of their power generating capacity. Most countries have tax and several other renewable energy incentives which radically minimize the price tag of wind turbines.

The price of an industrial turbine varies from $1.3 million to 2.2 million per MW. The typical modern utility turbines are 2 MW in size and cost approximately $3 million to $4 million.

The full costs for putting up a large-scale turbine differ much based on the number of orders made, financing expenditure, period when the equipment buying agreement was completed, assembly agreements, the site of the undertaking, and many more factors.

Chapter 9

Of all renewable sources of energy, wind energy is the most promising source in minimizing carbon emission. In the past decade, wind energy has experienced significant growth, and wind turbines are being constructed worldwide. It is the only renewable source of energy that can compete well with fossil energy- in some parts of the world, the eco-friendly, and safe power it produces is more cost effective compared to coal.

The demand for offshore turbines is rapidly growing, and the potential for energy production in water bodies is higher than in onshore, where wind speeds are weakened by rugged topography.

Small-scale, movable turbines are also being researched by engineers- although they are prototypical and consigned to niche markets- these machines may hit the world market quicker than expected. In a layman language, soon people will be floating turbines in their backyards, employ them to get off the grid, and providing their homestead with renewable and eco-friendly energy.

Chapter 10

Regarding the clean and renewable form of energy, people can bank on wind energy. With the blend of cutting-edge tech and reducing costs, wind energy adoption has risen in the recent past. Nevertheless, before it becomes the most reliable source of renewable energy, some obstacles must be overcome.

For instance, there are allegations that utility wind turbines trigger high degrees of bird mortality, and large turbines and blades are well known for bringing a wrong indigenous aesthetic. Fortunately, these problems are resulting in inventive solutions which are making wind energy a more appealing alternative. For instance, Vortex Bladeless firm has launched a revolutionary turbine that produces electricity without the necessity of spinning blades.

Thanks for being with us from the introduction part to the conclusion. Hopeful you have gained useful knowledge that will help you handle your wind turbine appropriately.

Place your order of wind turbine slip rings with MOFLON today and get the best of your money. WE NEVER DISAPPOINT!

Remember to leave your comment or question in the comment section below.