Welcome to our marine dredging and excavation guidebook.

In this guidebook, we shall learn the basics of marine dredging and excavation, the purposes of dredging, the types of dredgers, umbilical hose reel systems, marine propeller and propulsion systems, rotary unions and swivel joints.

MOFLON Technologies deals with the design, production, and distribution of marine dredging and excavation fluid solutions.

We have been in the market for over three decades, and we strive to attain our clients' project objectives by cutting costs, raising efficiency, and minimizing risks. We mainly deal with rotary unions, swivel joints, and slip rings.

We carry out our activities diligently to ensure that our workforce collaborates well and are accountable for the welfare and safety of themselves and users of our products, to avoid impacting the environment negatively and warranty high-quality products.

Contents

Chapter 1: Marine Dredging & Excavation Fundamentals.

Chapter 2: Why dredging is carried out.

Chapter 3: The types of Dredgers.

Chapter 4: Umbilical hose reel systems & Marine propeller and propulsion systems.

Chapter 5: MOFLON rotary joints and unions.

Chapter 1

Dredging and excavation are two popular methods of getting rid of sediments from a sea or an ocean, either when it is submerged (dredging) or after the water has been channelled to another location or drained (excavation).

Dredging and excavation are two popular methods of getting rid of sediments from a sea or an ocean, either when it is submerged (dredging) or after the water has been channelled to another location or drained (excavation).

Dredging and excavation keep oceans and ports navigable and support marine protection, land reclamation, and beach restoration. Marine dredging and excavation can also be carried out to recover valuable materials, like minerals or sediments like sand and gravel which are used in construction.

Dredging is a four-step process: slackening the material, moving it to the surface of the water, transportation, and discarding.

The components can be moved to the surface by suction or mechanical method. The material can be dumped or ferried by liquid suspension through large pipes.

Dumping can be to abandoned mines, or the extract can be utilized to replace eroded soil lost due to coastal erosion, or productively build sea-walls, constructing landforms like feasible islands in coral atolls.

Chapter 2

Maintenance

MaintenanceMarine dredging can be done to deepen or conserve navigable waterways that are under the verge of becoming silty, conceivably rendering them shallow for passage. This is done using a trailing suction hopper dredger.

A high percentage of dredging and excavation activities are done for this reason, and to retain the holding capacity of harbours.

Marine dredging and excavation can also be done to mine sand and other valuable rocks from ocean beds and utilize them in the building and construction industry. Besides, the extracts can be utilized to prevent soil erosion and floods.

This is done to make a harbour or passage, or to expand the available facilities to accommodate a bigger capacity. Since capital dredging entails hard components, the process is executed with the help of a cutter suction dredge.

This is dredging and excavation efforts done for future channels, piers, and wharves. It is carried out to lay a foundation.

Is done to reclaim regions affected by chemical spills, storm surges, soil contaminations like silt from sewage sludge and decomposed content such as wilted plants. Extracts from contaminant remediation usually are dumped.

Dredging can be done to lengthen the channel depth and consequently increase a harbor's capacity of holding more water.

A method for harvesting a particular species of consumable clams and crabs.

Chapter 3

They work by sucking via long pipes like some of the ordinary hoes, such as vacuum cleaners. Most suction dredgers have no equipment at the terminal of the suction tube to avoid interrupting the sediments. There are four types of suction dredgers:

Trailing suction.This type of dredger tracks its suction pipe when operating. The tube that is fixed to the dredger drag terminal collects the dredged waste into the hoppers of the equipment.

When these hoppers are fully loaded, the machine moves to a dumping site and either dispose of the components via doors or pumps the contents out.

Cutter Suction Dredgers (CSD).A CSD's suction pipe employs a cutting tactic at the suction bay, which loosens the sediments and moves it near to the section part. The extracted contents are drawn by wear-resilient centrifugal pumps and disposed of via a tube or barge.

Auger Suction Dredgers (ASD).Works like a CSD, but the cutting device is a spinning Archimedean screw fitted at 90 degrees. ASD is also known as turbidity shroud, and they generate high suction vacuums resulting in less turbidity compared to conical cutter heads; hence, they are mostly used for environmental purposes.

Jet-lift.They use the venture impact of intense high-speed brooks of water to drag the adjacent sea, coupled with sediments, into a tube.

Air-lift.It can operate just like other types of suction dredgers, but it is sometimes operated by a diver. Air is pumped into the tube, and since water is denser than the blown air, the air surges within the tube, sucking water with it.

Comprises of bucket and grab dredgers, which are strong enough to extract coral reefs to construct a waterway through the reef.

Bucket Dredgers.They contain bucket dredgers that collect sea bed materials by mechanical force, mostly with several circulating buckets fitted to wheels.

Grab Dredgers.It gathers sediments using a clamshell bucket that stretches from a crane. The method is mostly applied in the extraction of harbour mud.

Bed Leveller.Comprises of a bar that is dragged along the sea bed by water vessels.

Water Injection Dredgers.They use jets to pump water under minimal pressure (to inhibit the sea bed material from exploding into the adjacent regions) into the bottom of the ocean to move the materials in suspension.

Pneumatic Dredgers.They utilize chambers containing inlets, where water is injected with the channels shut. Pneumatic dredgers are customarily suspended from cranes, and their efficiency is based on depth pressure.

Chapter 4

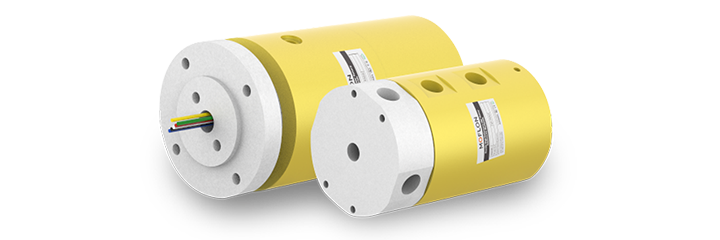

MOFLON manufactures fluid sealing products for umbilical hose reel uses calculated to bring operational flexibility for both onshore and offshore use cases.

MOFLON rotary unions/swivel joints incorporate well with umbilical reel systems permitting dependable winding.

Appropriate for pressures of 20,000 PSI and more, MOFLON Technologies' rotary unions offer hydraulic, pneumatic, and chemical services for umbilical reel systems. We provide standard and customized products with a broad variety of designs for single and compound movement channels, pressures, current volume, and media integration.

1.Pneumatic and hydraulic functions.

2.Bulk transportation/fuel supply.

3.Hose filling stations.

Below are the unique features of our rotary union products that make them outstanding in the market.

4.They are of high-pressure varieties (20,000 PSI and more).

5.Our rotary unions are of superflow volumes.

6.They are designed to meet specific customer requirements.

7.They are resilient to corrosion.

8.We have customized rotary unions for specific client specifications.

MOFLON's swivel joints permit 3600 rotation offering excellent elasticity of ejection pipeline flow. Our products are calculated to achieve the conditions set for modern marine dredging and excavation activities.

MOFLON swivel joints are generally available with high-pressure capacities (500 PSI) and for inner diameters of 300-1100 mm. Our swivel joints are designed using the redundant sealing invention, and users can service them minus disassembly eliminating the maintenance downtime issue.

Chapter 6

MOFLON rotary unions and swivel joints are appropriate for severe marine umbilical uses like installation, mediation, and workover. We believe in the steadfast tactic and commitment in retaining our position as the number one manufacturer and supplier of fluid sealing products globally.

We are continually researching and developing our manufacturing base and sales to realize more growth.

I hope you have enjoyed the guide. A pleasure to have you from the beginning to the end.

Remember to drop your questions in our comment section below.