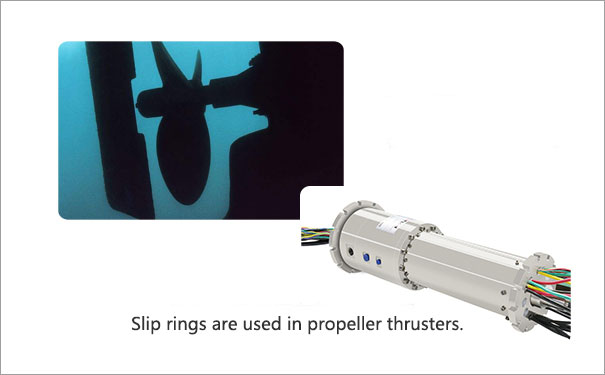

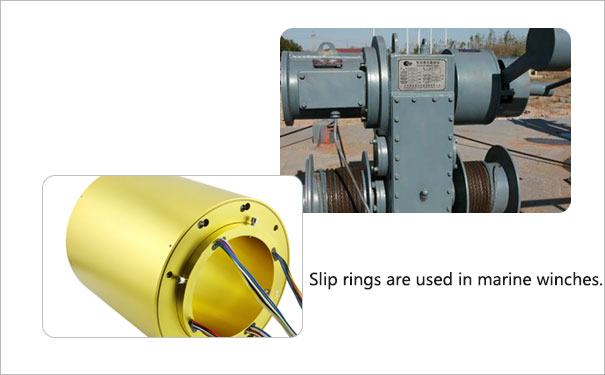

slip rings are an integral part of the marine equipment. The marine equipment in which the slip rings are commonly used is used for exploring marine resources, used for deep-sea mining and marine power generation. The slip rings are also used in crane use for mining, radar on the ships, winch and precise marine propeller system. These slip rings which are used in the marine industry come with heat abstractor and heating devices by effectively integrating photoelectric and high frequency and electricity.

Features

The carbon brushes used in the slip ring are made of advanced graphite alloy. This reduces the electrical noise produced by the slip rings and gives a stable connection. This is possible as the friction of the surface of the conductive rings with the brushes is reduced due to the use of graphite alloy. Also, the surface of the conductive rings is polished so as to minimize friction. Thus it helps in reducing the vibration and the shock generated during the operation of the slip rings.

Less Friction

There is a special sealing design applied for the slip rings. This seals the slip rings into its housing and does not allow any dust or debris or liquid to enter into the internal parts of the slip rings. If the dust enters the internal parts then they will corrode the surface of the conductive rings and cause an increase in friction of the brushes of the rings. If the dust and debris enter into the internals of the slip rings it will cause the slip rings to be stuck and hamper the operation of the slip rings. Liquids may also cause corrosion due to the acidic reaction of different parts of the slip rings. These effects may lead to the displacement of the conductive rings and the brushes causing to a breakdown of the arrangement or device.

Uninterrupted Transmission

They are equipped with heat abstractor and automatic heating devices. They can also transmit large amounts of current. This is because the arrangement of the rings and brushes is highly conductive and the high amount of insulation ensures the transmission is not interrupted or the transmission is not lost. The slip rings are more useful as they have a long service life and require low or no maintenance. This is because the debris generation due to the force of friction in the slip ring and brush contact. This is also the reason that the slip rings are vibration and shock resistant.

The use of slip rings has made a huge impact on the industry which is reflected in the number output figures put forward by slip ring manufacturer. There is a huge increase in the use of slip rings in the marine industry as they are customizable and are capable of carrying varying amounts of electricity and power signals. They are also capable of transmitting multiple signals simultaneously and have a long service life as they are resistant to vibration and shock. The slip rings have become the base of almost all operation and integral part of all the devices.