Basically, the slip rings are used for operating an immobilised part of an electrical machine. But due to space issue users can face certain problem regarding the equipment testing. If you need to take the strain and temperature measurement for your electrical tools or machines, the slip ring assemblies are beneficial.

These rings can also be referred to as slip ring assy. This product includes various specifications such as the electric slip ring, collector ring, precision conductive slip ring, brush and electric ring series. The brush can support 1~ 128 power and the signal line to the rotating device. And the electric slip ring can transmit all types of sensitive and bus signals.

Standard and customized slip rings are available to the customers. These assemblies have high resistance power and can work at maximum speed. It is also cost-effective and secured to use for every electrical application, in terms of space. The advantages of the slip ring assemblies are mentioned below:

1)These slip rings produce low electrical noise.

2)It does not need maintenance or cleaning procedure.

3)The bearings of the slip rings are permanently lubricated to make sure of wears.

4)It has the capacity to bear the high resistance.

5)A high volume of current can pass through the slip rings.

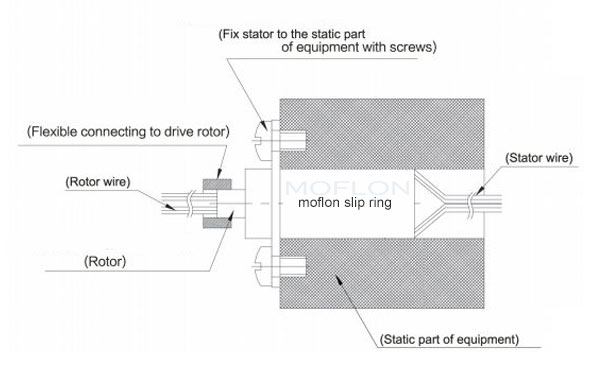

Slip ring In the modern electrical devices, the slip ring is centrally loaded on the rotary pole. A slip ring is an electromechanical machine that has two parts-- the stationary and the rotary body. It supplies the required current and signal from the rotor to the stator. The slip rings are used to clear the damage-prone dangling metal wires from the rotary joints. Hence, it is now in the perfect condition to perform in a smooth way.

There are other names of the slip ring as such the rotary electrical interfaces, rotating electrical connectors and swivels. The slip ring composed of a metal bodied brush which stroke to the rotating machine. When the metal brush and the slip ring comes in contact simultaneously it sends the power and signals. After establishing a connections, the data signals the current is transferred to the stationary body from the rotating structure.

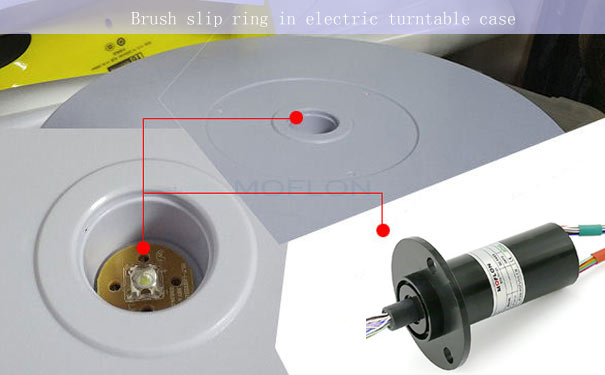

Function of slip ring The main reason behind the construction of the slip ring or electrical rotary joints is to activate the electrical machine like the AC or DC motor, generators, pumps, robots and drone machines. Now the queries arise relating to the function of slip ring in the electrical gadgets. The slip rings are installed on the central rotary device of the machine or equipment.

It consists of a metal brush that connects to the slip ring metal body and transmits the current and signal to the stationary structure from the rotary body. Some of the slip rings have an external resistance which has the capacity to conduct high resistance of voltage. It functions well when the speed of the current is increased. The slip rings can send high frequency data signals and power.