The modern times have seen a boom in the industrial sectors. And this increase in industrial production and the development of different industries has brought about immense improvement economic development of the countries. The industries have now improved the infrastructure. What used to be a hazardous working condition has turned into a friendly and healthy working condition. All this revolution has been brought about by the use of the new technology called the slip ring or the rotary joints. These help in the transmission of power and signals while achieving a continuous and simultaneous rotation of 360 degrees.

They are capable of transmitting various types of signals and voltages. And the use of these rotating devices has increased productivity and reduced the cost borne by the company. They have been a gift for the modern industries.

Workings and Structure

The principle on which a slip ring rotor works is very simple. They have a stator (stationary part) and a rotor (rotatory or moving part). These parts may be assembled separately or integrated together to form the slip ring assembly. The electrical or the data signals flow through the stationary part to the rotating part and vice versa with the help of a precious metal or advanced fiber contact brushes. These brushes are mounted on a brush holder and are placed in contact with the polished surface of the conductive rings. The spring helps to keep the pressure of the brushes stable on the rings.

Advantages of slip rings

The used of precious metal and advanced fiber brushes helps in reducing the corrosion of the brushes and in turn, helps to reduce the vibration. Due to this the electrical noise of the transmission that is going through the slip rings is reduced making them more suitable for operation in the industrial sectors and crucial machinery. The corrosion of the internal parts also may lead to the risk of the slip rings being stuck due to the accumulation of the debris in the slip ring and stopping the production and operation in different industries. This risk is also mitigated. The requirement of regular inspection and maintenance is also reduced as the corrosion is less. The cost of replacement of the corroded parts of the slip rings is also reduced.

The conductive rings have grooves and the brushes are fitted in the grooves this ensures that the brushes are not displaced causing a cross connection due to heavy vibration. Furthermore, the individual brushes and the conductive rings are insulated from each other with the help of insulating materials so that the transmission is precise and there is no loss in transmission.

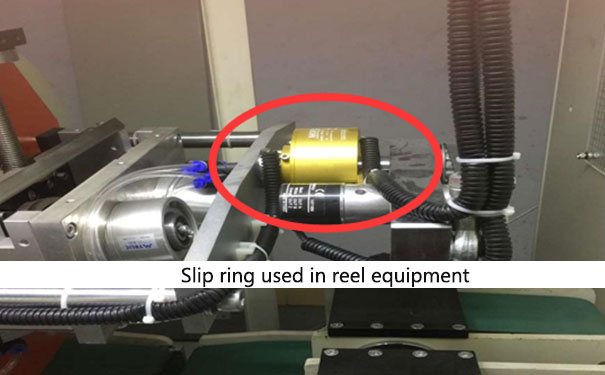

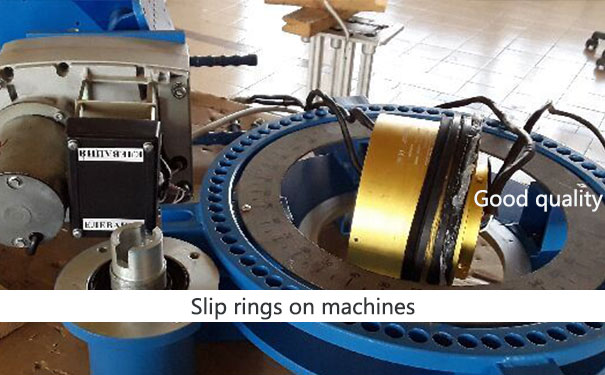

All these factors add up to what makes the slip rings more suitable than any other device to be used in the industrial sectors. The revolutionary designs and the ability of the slip rings to be fitted into almost every device are due to the different sizes it comes. The slip rings are not only being used in industrial applications but also in regular household devices for its usefulness