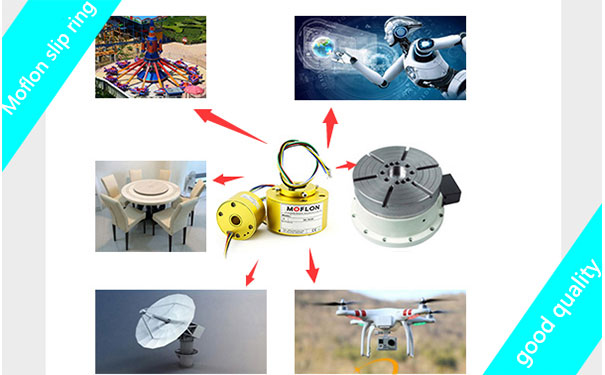

The use of slip ring has slowly progressed with the development of new kinds of equipment. It is for certain true that application of slip ring has increased. But the list of the new application has brought new challenges, which have made the regular maintenance of slip ring a necessity.

However, considering the fact that modern list of slip rings is designed in such a manner that they can tackle the harsh working condition, it does not take away the fact that they need to be maintained to keep the operational efficiency intact for a longer period of time.

When we talk of a list of slip ring applications, it is not complete until we mention some of the newer addition in the list, like the application of slip ring in robotics and satellite communication. But there are some of the application of slip rings like the ones often observed in defense and marine equipment needs a certain degree of maintenance regularity to adjust to the working condition and function at a higher level of efficiency.

Maintenance needs for slip ring used in the defense field

The very fact that defense equipment is supposed to be under immense harsh working conditions makes validation for the way in which they are designed. Now, to meet the power transmission requirement of such equipment, the slip ring manufacturer has designed a separate set of the defense slip ring. They are made up of quality material and the external surface has been made rugged and tough to withstand the pressure. In a nutshell, they are designed in such a manner that they don't break down in crucial situations.

Now the question arises, why is there need for maintenance when the slip ring is designed to soak in the pressure? The answer to that question lies in the second part of the question itself. The modern set of slip rings, like electrical slip ring absorb the pressure and nullify its harshness. But, doing that on a consistent basis makes the component of the slip ring, like brushes, wear out which results in the shortened lifespan of the slip ring. Here, we have just mentioned the brush, but there are few other components of slip ring which takes a beating due to continuous usage, which again in a way impacts the life and efficiency of the mechanism as a whole.

The need for maintenance of slip ring also becomes crucial because if we take the example of brush (if they are not maintained and checked properly), it would lead in curing extra amount to replace the damaged section of it. But in some case, replacing the entire unit of brushes or even in some cases, the entire slip ring unit has to be replaced. This, the crucial point of cost-effective for which the slip ring was initially used, goes for a toss.