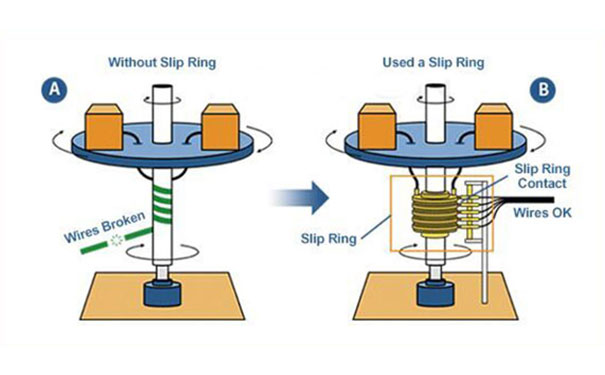

A slip ring is an electrical device that is used when a machine requires a supply power or data signals and rotate at the same time. It ensures that the current from the stationary wire is held in contact with a wire that requires to be twisted or rotated.

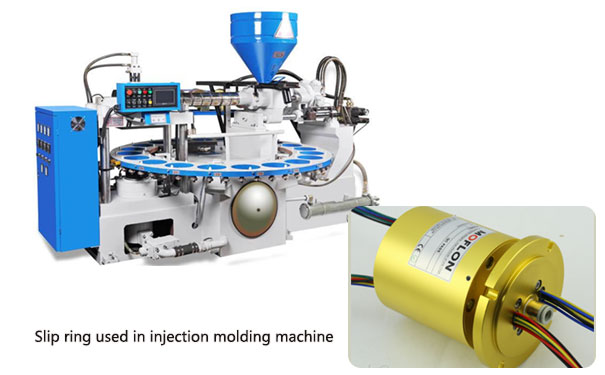

It is required in a number of systems, such as the CT scan machines, amusement rides in a park, closed-circuit TV camera, generators, radio telescopes and many more that require data transmission while spinning or rotating.

Choosing the right slip rings

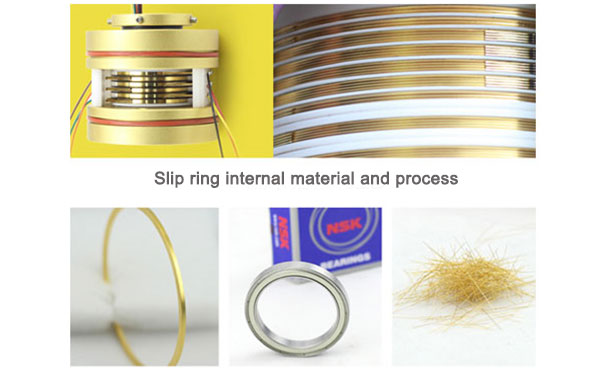

The material of the slip ring: Almost all the slip rings are made with metals like coppers, silvers, gold alloy, etc. The main thing that needs to be considered is the durability of the slip ring and should to be reliable enough for a long-lasting performance.

Low maintenance: Normally, a slip ring is selected on the basis of the performance and the maintenance. Though it is one of the main sources for the supply of power to operate the respective machine, the best type of slip rings are those that need minimum maintenance.

Environmental factors: To select the slip ring, the environment also plays an important role. Basically, the existing temperature and exposure to weather are the factors that need to be focused on.

Speed of the slip ring: The application of the slip ring is made on the basis of the rotations that it can deliver in a minute. Thus, the rotation per minute (RPM), can be one of the most important factors. Also, the speed of the rotation is considered since some of them are designed for an extremely slow spinning, like in the revolving door. On the other hand, a high-speed slip ring is required in jet turbine engines.

Structure and size of the slip ring: The slip ring is available in hundreds of sizes, each for its own compatible application. Some of the slip ring suppliers manufacture slip ring with custom specifications so that it can be suitable for different projects.

Slip ring brushes: The brush of a slip ring is an integral part of the mechanism. It looks like a paintbrush, with the only difference being it is made up of metal conductors which are dragged on the outside of the metal ring. When the device rotates, those brushes help to conduct the signals or the electrical current. It acts as the electrical slip ring connectors.

Test of the slip rings

A large component of the slip ring uses the brush contact whenever there is a rotating part. It uses the brush contact in order to pass the current between the stationary and moving parts, that is, the stators and the rotators. The testing of the slip ring includes the detection of the noise throughout the rotations and a high voltage separation between the rings.

Other tests consist of insulation resistance, continuity, dielectric strength and torque and rotational tests. The circuits should be capable of moderate fault level, if any, and the surge with no detriments. The brushes, terminal designs and gears need to be well proven to ensure the proper performance.