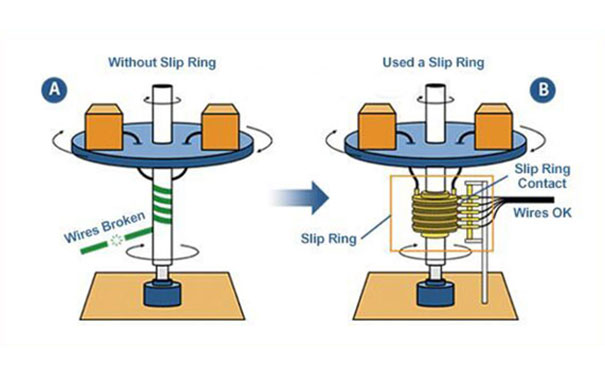

We have seen different kind of slip rings being introduced based on the functionality required for the equipment. For an instance, in the case of drone cameras, there was a need of slip ring which could meet the necessity of the 360 rotation. Also, the conventional slip ring could not meet the rotational requirement.

Thus, the slip ring manufacturer came up with electrical slip ring which could fit in the need for 360-degree rotation. This pattern of solving issues with the introduction of a new slip ring has been the trend for the last few years. Also, with the introduction of the new form of slip ring, the configuration aspect has become more dynamic and swayed from the general conventions. Here, we will be discussing the different aspects of slip ring configuration.

Slip ring configuration

The slip ring is designed in such a way that it operates on the physical layer. Thus, the parameter which is considered crucial here is directly linked with the transmission line. According to basic convention, any kind of electromechanical device incorporated in the transmission must possess the properties of the transmission medium. Some of the crucial factors that must be present in a transmission line before introducing a slip ring include - shield effectiveness and impedance matching.

Introducing an element in the transmission line which matches the properties of the medium is quite a tough task. Virtually, it is quite difficult to find a perfect combination or matching combination of the slip ring and transmission line.

Slip ring and compact assemblies

The introduction of a new form of slip ring is not just limited to meeting the parameters of the transmission line. One of the other factors that cause a change in the slip ring configuration is the installation space constraint. There are various types of equipment which has a low installation space and incorporation of orthodox slip ring is very tedious. Thus, we have smaller slip rings like through bore slip ring with a stark change in configuration than the conventional ones.

Space constraint and transmission line parameters

It is quite fascinating to note that the parameters of the transmission line and the space constraint are interwoven together. However, we need to first understand that slip rings are part of compact assemblies which thrive on de-rotation of multiple power, video and data signals.

Now, the plausible size constraint which comes of as no surprise as technology is evolving and poses certain issues in the performance of the circuit in the unstable matching impedance level and establishing a control on the crosstalk isolation.

In short, the changing face of slip ring technology, along with the sophistication of equipment, are currently dictating the choice of slip ring design and its configuration. However, the basic functionality of the slip ring remains the same with slight modulation to meet the changing requirements.