The slip ring belongs to the field of application of electrical contact slip connection,which also called collector ring, or rotary joint, rotating electrical slip ring, collector ring, return ring, coil, commutator, adapter, it’s precision transmission device which to achieve two relative transmission mechanism of the image, data signals and power transmission. It is particularly suitable for applications whereunlimited continuous rotation and where power or data is transmitted from a fixed position to a rotational position.

The slip ring is made of aluminum alloy shell, aluminum alloy axis, brush holder, brush,insulating strip, and wire,which is strong and reliable to use. It is loose with the shaft because the shaft and the slip ring have tolerance. Especially in the positive, reverse and braking conditions, the plastic will be broken after running for a period of time, which will create a certain gap with the shaft, and then loosened after several times of disassembly. If the looseness is serious, it must be removed. Replace the collector ring of the same specification or apply a layer of XH-fast adhesive on the inside of the original collector ring and replace it with the new one.

The loosening of the sleeve-type slip ring mainly occurs between the ring and the sleeve.Because the fit of the sleeve is insufficient. If not use the ring heat sleeve process, loosening will be more serious. After the ring is heat-set at 150°C, it is not easy to loosen. At the same time,it can be avoided the loosening phenomenon due to aging and insulation shrinkage of interlayer insulating.

The loose ring must be repaired in time. First remove the entire collector ring from the shaft, then remove the loose ring, and clean the outer surface of the original ring, and then reconfigure the new rings according to the outer diameter tolerance,the ring and sleeve fit tolerance should be H8/n4,heated the ring less than 150 degrees and put on the sleeve.

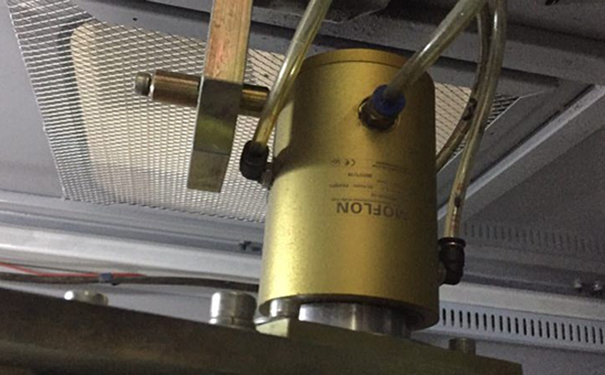

MOFLON slip ring uses gold-gold contact on the material, which can rotate 360 degrees smoothly without restrictions,it with low torque, low wear, low electrical noise, maintenance-free. The transmission rate is higher and more stable, which can meet More fields to use,

Tips:slip ring manufactory,looseness of slip ring