Alternators and transmission machinery almost always involve the usage of slip rings. For an almost inconspicuously mentioned piece of machinery, the slip ring is actually found in a huge variety of electronics and heavyweight gadgets. So what exactly is a slip ring?

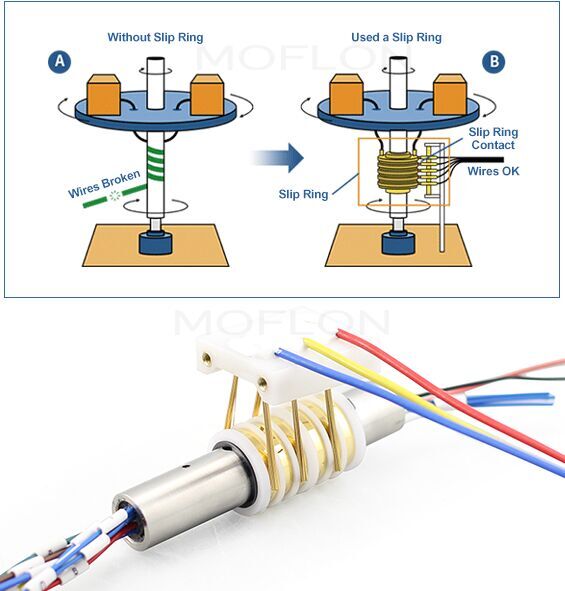

As per layman terms, it is a small device attached to a shaft that allows transmission between a rotating and a stationary device. The presence of the slip ring allows the rotor to maintain conductance with the stationary subunit of the machine constantly. This allows the rotatory unit and stationary to work together in an electrical assembly for the proper functioning of the device.

If you're still having a problem in realizing the concept, here's a quick real-life example. In a pottery barn, when trying to sculpt something, you keep your palms stationary, whereas the sculpting structure keeps rotating. Here there are no slip rings between your palm and the clay structure. The slip ring should, if there was any, would fit into the contact region. But in machines, the presence of an electrical slip ring improves the working of the device in several ways - improves the overall performance, makes it safer for heat-prone machinery etc.

So how a slip ring works is, it is fashioned of an immovable stationary contact - which is made of graphite or metal. The shaft maintains contact and rubs against the exterior diameter of the rotating metallic subunit.

As the rotor keeps running, electrical impulses move across the slip ring onto the stationary subunit. The slip ring brushes are made so they can conduct the maximum amount of electricity, i.e. the resistivity of the material they are made of has to be minimum.

To improve the electrical conductance circuit, multiple brushes may be configured into the system. In case of complex machinery, multiple slip rings with more than one brushes are an absolute requirement to get the circuits flowing in the most hassle-free manner possible.

electrical slip rings have been well in use for over ten years now, to ease the conductance of rotors to immobile machine shafts.

Alternative names of the Slip rings and types

Many engineers and mechanics often refer to the slip ring as the commutator. But commutators are not to be confused with the actual device, which forms the core of DC and several motor generators.

The two terms are however often interchanged due to the sheer similarity of function of the two.

Here are two quick differences between a commutator and slip ring:

1. Slip rings are a smaller and lighter version of commutators.

2. While Slip rings are continuous, commutators are larger and more segmented.

Other common acronyms used are the collector ring and the rotatory electrical subunit. It is quite evident by the variety of names, what exactly is the function and mechanism of the slip ring.

Slip rings are also of many types (such as the mercury wetted slip ring, pancake slip ring, wireless slip ring), making it an ideal catalytic device in a wide range of machinery.