- Home

- About Us

-

Products

- >Slip Rings

- >Rotary Unions & Hydraulic Swivel Joints

- >Fiber Optic Rotary Joints(FORJ)| Microwave, RF, High Frequency| Waveguide Rotary Joints

- >Fiber Optic Gyroscope & Coils

- >CT Slip Rings

- >Wind Turbine Slip Ring

- >Military Grade Slip Rings

- >By Industries

- >Rotary Customized Solutions

- >Cable & Hose Reels

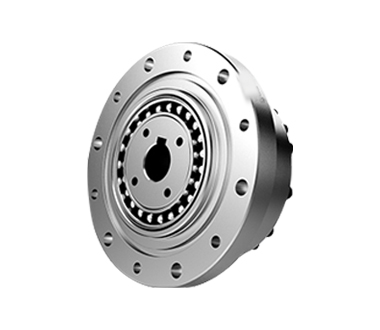

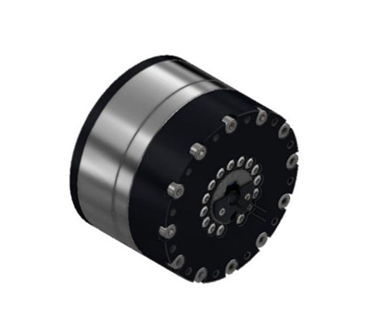

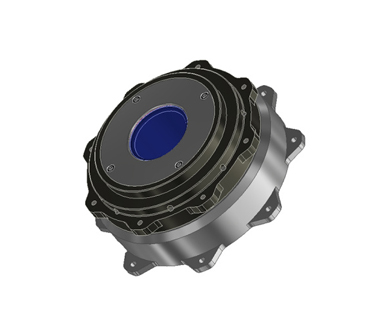

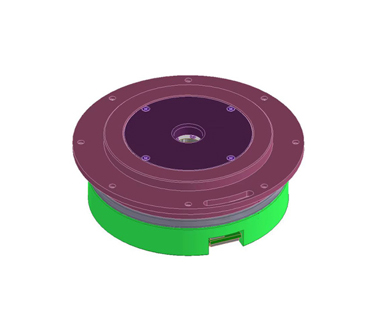

- >Harmonic Gearbox & Actuator Module

- Technical Support

- Online Enquiry

- News

- Contacts

Blog

Blog

Download

Download

Videos

Videos

Buy Online

Buy Online