The quest of harnessing wind energy in a better than the existing way has been quite a never-ending pursuit of mankind. The rampant rate at which the non-renewable source of energy is being put into use for different commercial purpose leaves us with the no choice but to look into the alternative source of energy. Harnessing wind energy is one of the potential sources of renewable energy on which we are banking on currently. But, the path of harnessing wind energy is littered with technical and financial challenges.

Somewhere down the line, both the financial and the technical challenges are correlated to each other. During the initial phase, when the idea of harnessing wind energy first took a real physical shape in the form of wind turbines setups, there was a lot of apprehensions. For an instance, the private investors would pull out from the project because the technology was not advanced for inducing any kind of positive results. Also, the amount to be invested was quite huge, which added the skepticism of the investor leaving the government behind reeling on its own.

Things began to change with the development of technology

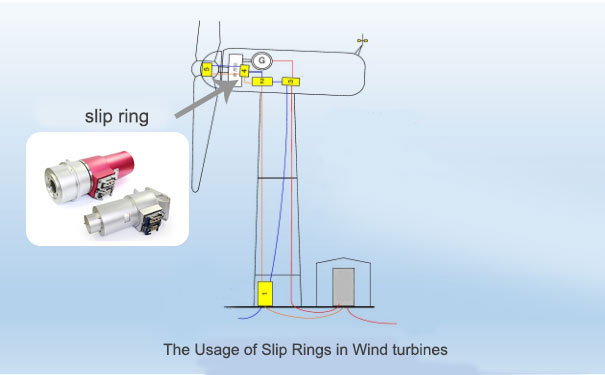

One of the concerning issues was the transmission of power and electricity in the important rotating and electrical component of the turbine setup. Without proper power and electrical signal, the chances of efficiently harnessing wind energy were remote. Although, the turbine operators used long cable wires to transmit the regular electrical signal, there were a couple of downside of using the stack of cable wire. Firstly, the installation process was quite complex and secondly, it was not a cost-effective method.

With time, the turbine operators were exposed to something called a slip ring, which could cater to the requirement of transmission and power signals. The slip rings eliminated both the drawbacks of cable wires as they could be easily installed owing to its simple design and it was cost-effective.

The modern form of slip ring - the turbine slip ring

As mentioned earlier, the existing method of harnessing wind energy needed regular upgrades due to increasing operational requirements. As more and more advanced rotating equipment began to be installed in the turbine system, it did not operate in a desired way with use of conventional slip ring.

The answer to the coping up with modern equipment was in the development of slip ring technology. As the technology evolved, newer forms of slip ring came into the scene and for solving the problem of a wind turbine, a special type of slip ring was designed.

Although some of the modern slip rings, like the electrical and the high current slip ring was quite up to the task, the need for a specific form of slip ring grew innately. Thus, came in the turbine slip ring, which had the properties of both electrical and high current slip ring.