slip rings are very often considered to be simple electromechanical devices, so it is quite natural to think that to meet the end result of quality processing a design approach would do the deal. Also, it is quite natural that there is a preconceived notion that the number of challenges in designing a slip ring would be menial. However, this line of thought is a stark contradiction when compared with the thought process of the engineers, according to them designing a slip ring is as complex and filled with challenges as is the ease with which the slip ring performs in real time.

Factors that are needed to be taken into consideration for designing a slip ring

As mentioned earlier, designing a slip ring is no cakewalk, especially, when the need of the hour is to regularly provide high-quality slip rings which could meet the unprecedented rise In the technologically advanced equipment. To be precise, the factor which may affect the design cue of a slip ring includes the need to handle mixed signals, contact resistance potential, high-frequency signal transfer and finally RF shielding. Some of the other factors that affect the environmental conditions, operational condition packaging limitation and life cycle of the product.

Challenges for developing ethernet based slip ring

The way industrial technology has shaped up in recent times is simply something to take note off. One of the probable reasons for such a thumping progress is the introduction of a chain of internet connectivity in different lines of industrial production, which simply bolstered the entire process of production. Having said that. The amount of high-frequency signals being transmitted is simply huge and it is not just about the quantum of signals to be transmitted, but it is also about the quality of the signals being transferred.

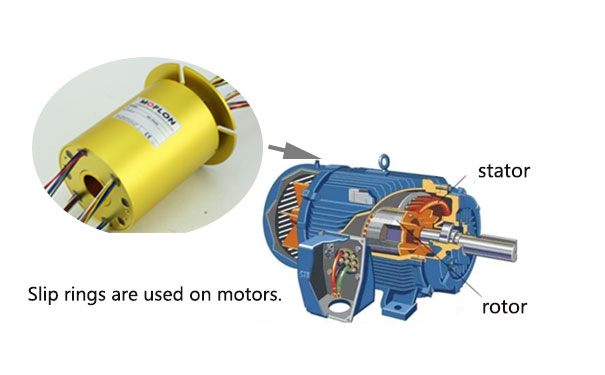

The list of Ethernet signals to be transferred is long and varied. Thus, the need for premium ethernet sip ring becomes almost innate. Now, there is the inherent challenge of designing the ethernet slip ring in such a way that different kind of frequency signal can be handled, but apart from the aforesaid challenge, there is an additional challenge of dealing with the electromagnetic interference. It should be clearly understood that transmission of frequency signals takes place at a rapid pace. The nimbleness of signal transmission is hampered by the external electromagnetic or so to speak, electrical interference. The power channels which generate EMI in the motor equipment.

Dealing with EMF interference

To eliminate the negative effect the engineers employ an apt RF design technique. Along with approach of employing effective RF shielding they (engineers) also inculcate modern slip ring technology, which introduces an effective way to maintain a considerable amount of physical space between the source of electrical interference, it reduces the level of interference in the actual operating environment.

The engineers also ensure that the shield employed has a distinct channel within the slip ring. The argument for having a distinct operating channel is that it would further help in establishing an electrical connection between the rotor and the stator shield. This further allows a proper path for conduction of electricity in the midst of interference.