Excitation of a Synchronous machinery is almost like a remotely related word to the slip ring industry. The production of flux by means of passing the current in a field winding is called excitation. The entire system that has this arrangement, which is used for excitation of a synchronous machine is called the Excitation system.

A mechanism would require direct current in order to excite a field winding of any rotor of a synchronous machine. A DC current generator is added to the mechanism called Exciter, which is responsible for the supply of direct current to the small machine, or precisely, the rotor field. Moreover, the power or current that is supplied to the Exciter by a small generator of direct current, which is called Pilot Generator.

Assembling of the Synchronous motor

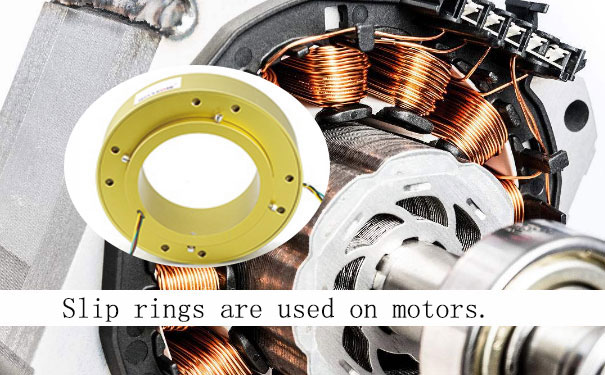

Both the Pilot Generator and the Exciter are mounted on top of the main shaft for a Synchronous motor or generator. However, there is a slip ring assembly here as the direct current from the Exciter is passed on to the winding field of a Synchronous motor with the help of slip rings and their brushes. However, the Pilot Generator is not included in the smaller machinery.

On the contrary, for any medium-sized machine, the direct current Exciter is replaced with an AC Exciter. These AC Exciters are basically a three-phase generator. The output from an AC Exciter is first rectified and then is supplied through an electric slip ring and brush to a rotor winding.

However, for any large synchronous motor or generator, that has hundreds of megawatt rating, the entire Excitation system becomes necessarily large. Under such a situation, the problems of transmitting such high power and current call for a more formidable contact through a very high-speed sliding mechanism.

An excitation system for large Synchronous motors or machinery

At present, all of the large Synchronous machinery use the Brushless system for Excitation. Now the mechanism of any Brushless Excitation System for a large Synchronous motor is quite complex. The brushless Exciter is like a small directly-coupled Alternating Current Generator. The field circuit of this brushless system remains of the static component (stator) while the rotor (rotating component) has the armature circuit.

A solid state rectifier rectifies the three-phase output that comes from the AC Exciter generator. Here, the rectified output power is directly connected to the winding field, which in turn eliminates the use of any slip ring or its brushes.

Conclusion

Using a Brushless Excitation system does not require a very high maintenance as it does not have slip rings as its component. Even the loss of power is brought down by a good margin. The required direct current for the mechanism is supplied by an Exciter, which is attached to a Pilot Generator. Plus, it is because of this Pilot Generator Exciter that makes the entire mechanism independent from all kind of external supplies.