The basic idea behind the use of carbon brush in the transmission of signals has been discussed quite often. But the key points which are associated with fitting the brush and the holders are not often discussed. Here we will be looking into different aspect fitting the brush and the holders.

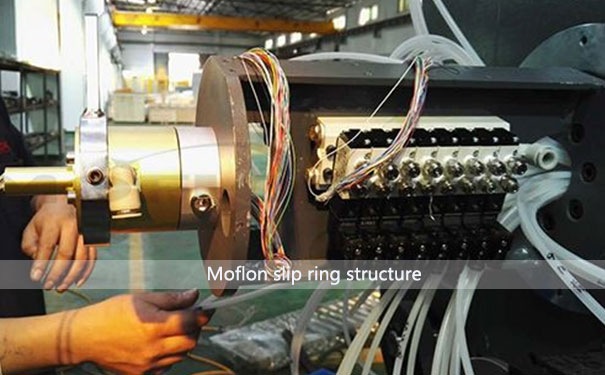

The clearance between brush holder and collector

Initially, the brush holders are fitted in the system in such a manner that the distance between the collectors and the lower edge of the holder is kept at 2.5 mm. Also, in cases where the said distance is kept below 2 mm and more than 3 mm, the holder needs to be readjusted with the use of holder clamp assembly. In some of the other situations where the distance cannot be re-adjusted using the holder clamp assembly, the users can resort to adjusting the brush arm.

The angular aspect at which the collector and the brush meet also needs to be taken into consideration. With respect to getting the angles, correct users must seek the advice of a technician or follow the standard parameter set by the slip ring manufacturer.

Design arrangement based on spring pressure

As per the norms, the entire set of brushes must work under the same level of pressure to avoid any kind of disruptions. On the sidelines, the entire brush unit and the holder must be cleaned regularly and the pressure must be recorded by using the spring balance.

Constant force springs

The general characteristics of a CF spring bring out the fact that the force always remains constant over the entire range of ring extension. The level of force applied dwindles only in certain specific conditions. With the spring entering the brush box the force usually remains the same. The real test of the slip ring and brush along with the brush holder is observed in its application in traction motors. The reason being vibration and the shock at which the slip rings are being subjected gives a fair idea about the tenacity of its component mainly the brush holders.

Under such working condition, the CF spring brush holders always have an upper hand than the conventional form of slip ring brush holders. Also, the increase in the number order received by the slip ring suppliers is a testimony to the fact that the CF spring brush holders are fast replacing the conventional ones.

Insulation

The past several experiments on the spring and the brush have brought forward some interesting facts. The experiments conducted highlighted the fact that there is no such considerable change in the flow of current if the flexible brush gets disconnected for a certain period of time. However, it is always advised to insulate the spring from the brush. The spring can be insulated by introducing a non-conduct element at the top end of the brush just where the spring connects the brush.