A slip ring is an electromechanical device that enables the transmission of power and electrical signals from a stationary to the rotatory body. Most of a modern lot of slip rings, like electrical slip ring, are composed of conductive rings made of highly conductive materials. Such slip rings make way for an extensive application in some of the major areas like the defense. In such slip rings, the brushes are made of carbon which is also considered to be a great conductor of electricity. They also have brush holders and springs and a housing made of aluminum alloy.

The slip rings, though being a highly useful device and having brought revolutionary changes in the industrial sector, is still faced with problems and one of them is heating of the components. This is one of the major issues which hinders the efficiency of the slip ring. But what causes the heating? To understand this, we first need to understand how a slip ring assembly works.

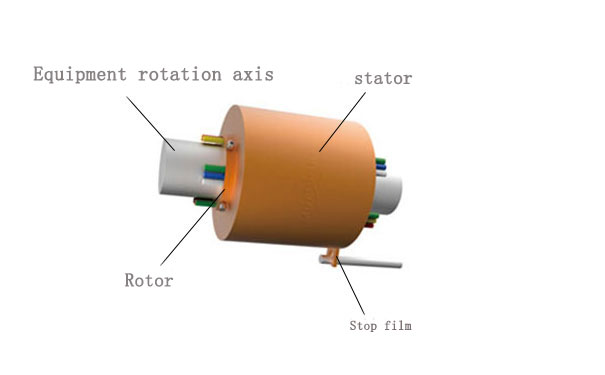

Working of a slip ring rotor

A slip ring helps in conducting electricity from a stationary to a rotatory body. The rotatory body consists of conductive rings. The stationary body consists of contact brushes, brush holders and springs. The electricity passes through the conductive rings and then on to the contact brushes, which are constantly rubbing against the surface of the conductive rings. The brush holders help to keep the brushes in place. Maintaining the pressure of the brushes on the conductive rings is necessary to ensure that the proper contact between the rings and the brushes is established so that there is no disruption in the connection.

Why do the brushes heat up and how can the heating be reduced?

As mentioned earlier, the brushes of the slip ring rub against the conductive rings which induces friction. Due to this friction, the carbon brushes heat up, and since they are brittle, they tend to get corroded due to friction. The heating of the brushes is further increased by the corrosion of the conductive ring surface and the constant friction of the brushes with the debris generated due to friction.

This heating can be reduced by the use of fiber brushes made from advanced technology. And polishing the surface of the conductive rings to provide less friction. This also reduces the generation of debris and in turn, reducing the heating of the brushes. The springs behind the brushes also help to reduce the friction by maintaining proper pressure on the conductive rings. Too much pressure may lead to high friction and cause corrosion. Moreover, the assembly is placed in an alloyed aluminum housing, sealing it from the outside world and making sure that dust particles do not enter and cause corrosion due to friction with the rings and brushes or cause acidic reactions.