When the slip ring first made its entry into to the industrial scene, it did not garner a wide range of application. The reasons were evident, and it surfaced time and again in the form of inefficiency in adjusting to different conditions.

Initially, the slip ring was used in core industrial fields, which included the equipment used in production plants. The working of orthodox slip ring adds only a certain level of operational efficiency. Also, considering the fact that in those days the equipment was not too advanced to cause any operational blocks.

It was only with time that the wave of modernization brought a host of a different kind of equipment that posed challenges for slip ring manufacturer. Further, the conventional slip ring that covered a major portion of the slip ring industry which could not adapt to the need for modern equipment. Hence, it comes off as no surprise that list of application of orthodox slip ring could not pick up.

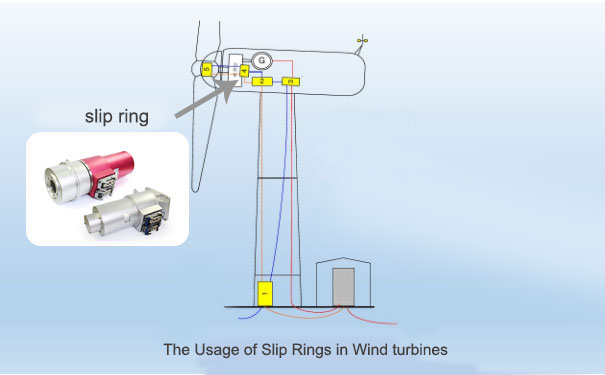

The reason we see today a wide range of application of slip ring is due to the technological advancement of the same. Also, such slip rings could easily meet the changing requirements of the modern equipment. Here, we will see the latest application of slip rings in wind turbines.

Application of slip ring in wind turbines

The effect of the downside of the orthodox slip ring also had an impact on the capability of the wind turbine to harness wind energy. As a matter of fact, there came a situation when setting up new turbines were considered a waste of resources. The primary reason for such a notion steamed from various reasons, but one of most crucial elements which gave rise to such a notion was the absence of the right kind of slip ring.

Harnessing wind energy through the wind turbines required a transmitting medium which could transmit both the electrical and data signal. The electrical signal needed to be transmitted for the pitch control system. While the data signal were to be transmitted to the main control unit containing important packets of information.

To cater to the above needs the slip ring manufacturer came up with, especially designed, turbine slip rings. Such slip rings were considered to be quite sturdy and made of precious metal which lent a certain level of ruggedness to the slip ring. As a result of which such slip ring could easily adjust the harsh of the conditions around.

With turbine slip ring it was not just tackling harsh condition, it also transmitted required signals with ease. Further, such slip rings could easily be customized with and all the important components could easily be added.

The introduction turbine slip ring nullified the strong notion of setting up a new turbine is a waste of resources to absolute zero. In fact, today with the advent of turbine slip ring the entire process of harnessing wind energy is made more efficient.