The separate slip ring is a slip ring that is derived from an independent unit that is capable of transmitting current and data signals from a stationary to a rotatory part. The conductive rings and the rotor are assembled as separate parts of the slip ring assembly. They are furthermore customizable as per the customers.

Features of the Separate slip rings

The stator and the rotor are separate from each other and are assembled from each other to form the slip ring. They have the capability of transmitting power along with weak signals. Since the stator and the rotor are separate parts of the slip rings forming the slip ring assembly they can be assembled in various ways and according to the requirements of the industries, they are more preferred for the use.

Advantages of Using Separate Slip Rings

They offer low resistance to the electrical signals and as a result, the transmission is smooth and there is no loss of data is the transmission. This is achieved by the use of precious metal contacts and the smooth polished surface of the conductive rings. This lowers the friction of the brushes on the rings. They also help in reducing the corrosion of the brushes and reduce the vibration. This helps in reducing the risk of displacement of the parts of the slip rings which may cause a stop in transmission. Separate slip rings are easy to install and are capable of being fitted and being operated in constricted spaces allowing the increase in the functionality and suitability of the slip rings.

The slip rings generally have a long lifespan. The brushes are made of an advanced fiver or specious metals. This helps in reducing the wear of the brushes due to friction and chemical reaction from the outside environment. They are capable of working in adverse environmental conditions. Since the dust generated due to the wear of the brushes is less the vibration of the slip ring rotor is less and in turn, the risk of displacement of the parts of the rotor is reduced. The slip rings are also not stuck due to the accumulation of the debris hampering the production. The cost of replacement of the brushes due to wear is minimized which reduces the maintenance required at regular intervals. The corrosion of the conductive ring surface is also reduced and this increases the efficiency of the transmission and reduces the electrical noise.

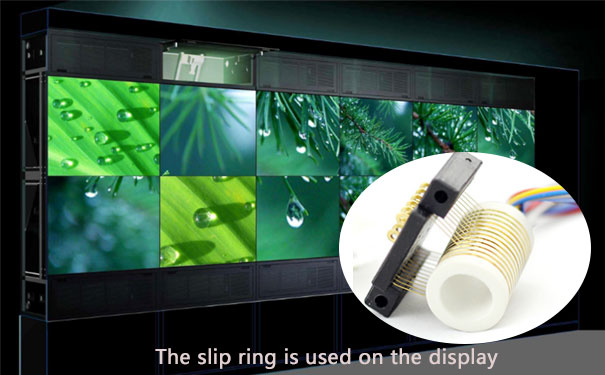

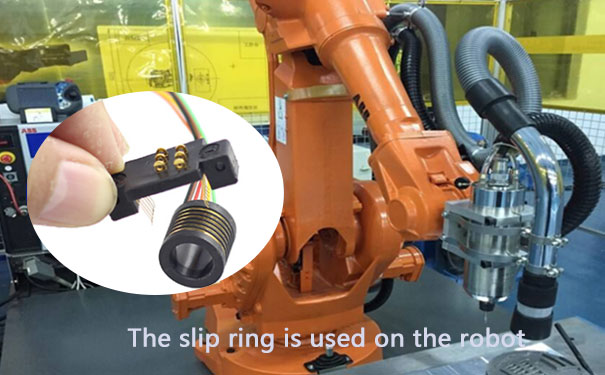

The biggest advantage of using the separate slip rings is that they have an arrangement which is separate and they can be fitted into almost any shape and require installation space for operation. They are becoming more and more used in the industrial sector causing the industries to conduct research and development in the slip rings field to provide a better solution.