There are various aspects which, as a whole, constitutes the entire process of carbon brush maintenance. Here, we will be discussing the measurements that need to be taken when the machine is at standstill and the key points that need to be observed when the machine is at a halt.

The slip ring manufacturer has laid down certain standard parameter under which crucial elements like temperature and voltage must fall. If there is any deviation from the standards set, the users have to look for the fault in the slip ring assembly unit. This deviation can occur for any given reason, but here we will be focusing on the deviation that can be caused by inappropriate maintenance of carbon brush.

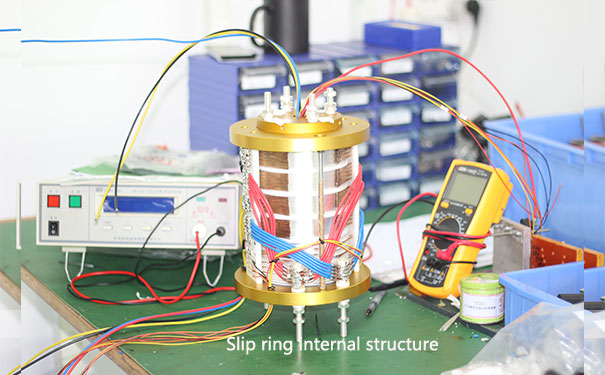

Measurement related to the electrical aspect of the machine

There are certain parameters that are related to the electrical aspect of the machine and one of them is resistance. Here, the user needs to measure the insulation resistance of the different type of components attached to the circuit. This has to be done both after and before the dust is removed from the surface. This leads to ascertain the effectiveness of the carbon brush operation.

The measure of resistance is important as all the other electrical elements depend on the resistance level. The voltage that flows through varies with any variation in resistance. Also, the level of current flow that is introduced in the system, in case of variation in the level voltage, is dictated by the resistance level.

.jpg)

The users must run a check on the air gaps at all four crucial points in four different intervals with the right set of feeler gauges. After accumulating the data, the average figure must be compared with the standard figure laid down by the slip ring suppliers. In comparison, if there is any deviation from the standard set, it gives a fair idea about the state of bearing clearance.

Brush holder and brush clearance

The brush holders are an integral part, which, at first, holds the stack of brushes in a certain shape and at a certain angle. There are certain steps which must be followed to keep the brush and brush holders in good working condition, thereby, auguring the carbon brush performance and slip ring at large.

The user must check the stability of the carbon brush by running a check on the brush and the carbon brush clearance. Further, the user must check the working state of the internal surface of the brush holder because, at the end of the day, it is the brush holder that helps to establish an effective sliding contact between the slip ring and the brush. Finally, the distance between the carbon brush holder and the consultative ring must be monitored regularly and adjusted according to the situation. Usually, a distance of 2.5 to 3 mm is found in most of the equipment.